A Deep Dive into Transformer Oil Purification Methods

Why Transformer Oil Need Purification

Over time, transformer oil may be contaminated with various impurities, such as moisture, gases, and particulate matter. These pollutants will seriously reduce the performance and stability of transformers, leading to potential failures and increased maintenance costs. Transformer oil mainly has the following types of pollution:

- Water pollution: Water can enter transformer oil through leakage or condensation, reducing its insulation performance and potentially causing short circuits.

- Gas pollution: Gases such as oxygen and carbon dioxide can dissolve in oil, leading to oxidation and acid formation, further reducing the performance of oil and transformer components.

- Particle contamination: Solid particles generated by internal component failures can contaminate oil, affecting its effective insulation and cooling capabilities.

Purifying transformer oil is crucial for maintaining its quality and ensuring the long-term reliability and efficiency of transformers. Regularly purifying transformer oil helps to remove these pollutants, thereby preventing damage and extending the service life of the equipment.

Key Transformer Oil Purification Methods

Transformer oil purification is a crucial process to maintain the efficiency, performance, and longevity of transformers. several oil purification methods are commonly employed:

1. Filtering

The filtration method is one of the most common methods for purifying transformer oil. It involves the use of different types of filter media, such as paper, cloth, or synthetic materials for filter cartridges. During the filtration process, transformer oil is forced to pass through these filtration media to remove solid impurities. In order to improve filtration efficiency, a multi-stage filtration system can be used, where the pore size of each filtration medium gradually decreases to remove smaller particles.

2. Heating

The heating method is mainly used to remove moisture from transformer oil. Water may exist in oil in a dissolved or free state. By heating, the oil temperature rises, and the water evaporates into steam, which can then be separated from the oil through condensation or other means. The heating process needs to be carried out in a controlled environment to prevent oil overheating or oxidation.

3. Vacuum pumping

Vacuum pumping is an efficient method for removing gases and moisture from oil. During this process, the transformer oil is placed in a sealed vacuum container, and the atmospheric pressure in the container is reduced to a level far below normal atmospheric pressure. This pressure difference causes the dissolved gas and water in the oil to quickly evaporate and be extracted from the system. The higher the vacuum degree, the better the effect of removing water and gas.

4. Pressure filtration

The pressure filtration method is usually carried out on-site, which uses pressure to pass transformer oil through filter paper or other filtering media. This process can not only remove solid impurities, but also remove water from the oil through the water absorption of the filter paper. This method is suitable for quickly processing large amounts of transformer oil.

5. Electric oil filtration

The charged oil filtration method is an oil purification method carried out while the transformer is in operation. In this method, the oil filtering equipment is connected to the transformer, and the oil is purified through the oil filter during the flow process. The advantage of this method is that it does not require stopping the operation of the transformer, but special attention needs to be paid to safety measures to ensure the safety of all equipment and operators.

6. Chemical cleaning

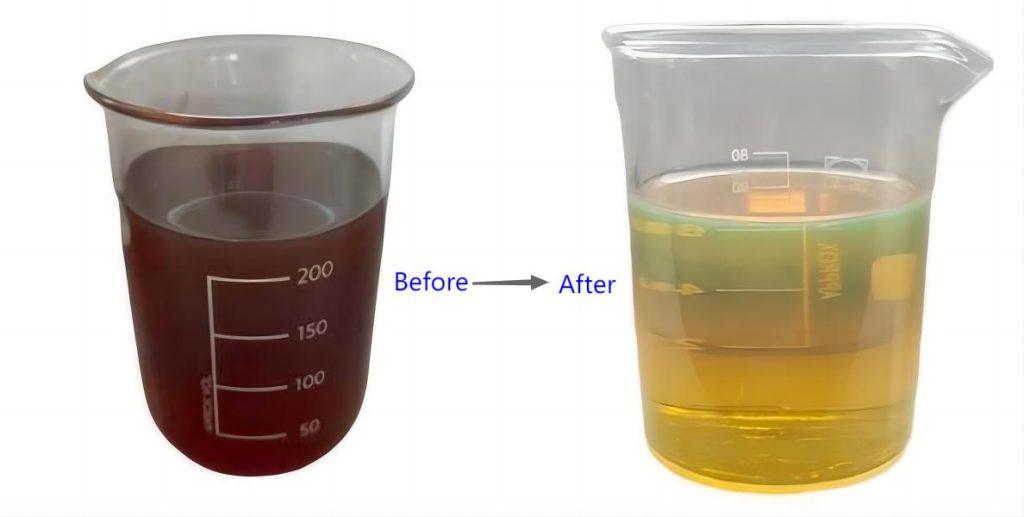

The chemical cleaning method uses special chemical cleaning agents to remove pollutants from the oil. For example, the neutral chemical cleaning technology provided by Baros Group can effectively remove oil sludge and other deposits without damaging the internal components of transformers. This method is commonly used for heavily polluted transformer oil or as a supplement to other purification methods.

When purifying transformer oil, appropriate purification methods should be selected based on the specific degree and type of oil pollution. Sometimes, it is also necessary to combine multiple methods to achieve the best purification effect.

Transformer Oil Purification Machine or Other Methods?

In addition to these methods, Transformer Oil Purification Machines are also used in the power industry, it exhibits different characteristics from conventional transformer oil purification methods.

- Transformer Oil Purification Machine

Transformer Oil Purification Machine is a mechanical device specially used to filter solid impurities, moisture, and gas in transformer oil. This equipment usually includes components such as a primary filter, heating system, vacuum separator, and filtration system. When working, the oil enters the primary filter under the action of internal and external pressure difference, and large particles of impurities are filtered out. Then, through heating and vacuum treatment, the moisture and gas in the oil are quickly vaporized and discharged, and finally, clean oil is obtained.

- Transformer oil purification methods

Transformer oil purification methods refer to a series of technologies and steps used to improve the quality of transformer oil. These methods may include mechanical filtration, centrifugal separation, vacuum filtration, chemical treatment, etc. Each method has its specific application scenarios and advantages. For example, mechanical filtration is suitable for removing large particle impurities in oil, while vacuum filtration is suitable for deep degassing and dehydration treatment.

Generally, the transformer Oil Purification Machine is a specialized equipment suitable for occasions where transformer oil needs to be treated quickly and efficiently, especially in on-site maintenance and new oil treatment. Transformer oil purification methods provide more flexibility, and the appropriate treatment method can be selected according to the specific problems of oil quality. When choosing which method to use, the actual application scenario, treatment requirements, and economic factors should be considered.

For large-scale oil treatment or occasions that require frequent treatment, a transformer Oil Purification Machine may be more suitable; for specific oil quality problems or limited budgets, choosing an appropriate purification method may be more cost-effective.

Conclusion

Employing a combination of purification methods ensures that the oil remains free from contaminants, thus preserving its insulating and cooling properties. However, the use of a transformer oil purification machine stands out for its efficiency and comprehensive approach, making it an essential tool in modern transformer maintenance practices.

If you are in need of a transformer oil purification machine, Contact YUNENG right now.