An Essential Guide to Double Stage Transformer Oil Filtration Machines

Electrical transformers play a pivotal role in power distribution systems, facilitating the efficient transmission of electricity. To ensure the optimal functioning and longevity of transformers, maintaining the quality of transformer oil is crucial. Over time, contaminants such as moisture, gases, and particles can compromise the dielectric strength and insulating properties of the oil, leading to a decline in transformer performance. In response to these challenges, double-stage transformer oil filtration machines have emerged as essential tools in the maintenance and preservation of transformers.

This article delves into the Working Principles of double-stage transformer oil filtration machines, explores their benefits, examines their applications, and concludes with a reflection on the significance of incorporating these machines into routine maintenance practices.

Working Principles of Double Stage Transformer Oil Filtration Machines

- Commencing the procedure, the oil first moves through a preliminary filter before entering a heating unit.

- Within the vacuum separator, the heated oil experiences a separation process, facilitated by the simultaneous operation of a vacuum pump and roots pump.

- Following this, the roots pump channels the oil towards the condenser, concurrently extracting water vapor molecules into a water receiver.

- As the oil is propelled by the oil pump, it undergoes further processing through a secondary filter and fine filter before its final stage.

Here are the operation steps:

- Employing the vacuum pump to create a vacuum by expelling air from the vacuum tank.

- External oil is introduced into the primary filter via the oil inlet pipe, where larger particles undergo removal.

- Prior to automatic regulation by the oil float valve, the oil undergoes heating in the heating tank, reaching temperatures between 45 and 65℃.

- The heated oil undergoes a rapid rotation within the jet wing, resulting in its dispersion into a semi-mist. This process causes the water in the oil to evaporate into vapor, which is then suctioned into the condenser by the vacuum pump.

- The water vapor, now in the condenser, undergoes cooling, leading to its transformation back into water and subsequent release.

- Using the oil discharge pump, the oil is expelled from the vacuum degassing and dehydration chamber, with a fine filter responsible for the filtration of fine particulate impurities during this process.

Benefits of Double Stage Transformer Oil Filtration Machines

1. Enhanced Oil Quality

The primary benefit of double stage transformer filtration machines is the substantial improvement in the quality of transformer oil. By effectively removing impurities, moisture, and gases, these machines contribute to the creation of high-quality oil that can better withstand the operational demands placed on transformers.

- Extended Transformer Life

The enhanced quality of transformer oil directly translates to an extended lifespan for transformers. By mitigating the impact of contaminants, double stage filtration machines play a pivotal role in preserving the integrity of the transformer and its components, contributing to long-term reliability.

3. Improved Dielectric Strength

Dielectric strength is a critical parameter for transformer oil, and maintaining it at optimal levels is vital for the insulation system. Double stage filtration ensures the removal of contaminants that might compromise dielectric strength, reducing the risk of electrical failures and breakdowns.

- Prevention of Corrosion

Moisture and other corrosive elements present in transformer oil can lead to the corrosion of transformer components. Double stage filtration machines, particularly those equipped with vacuum dehydration units, effectively remove water and prevent corrosion, preserving the structural integrity of the transformer.

5. Increased Operational Efficiency

Clean transformer oil facilitates efficient heat dissipation, a crucial factor in the operation of transformers. By removing contaminants, double stage filtration machines contribute to the optimal functioning of transformers, minimizing the risk of overheating and ensuring smooth and reliable operation.

Application of Double Stage Transformer Oil Filtration Machines

The Transformer Oil Filter Machine, a silent sentinel, plays a pivotal role in diverse industries. Primarily utilized in the power sector, including power stations and companies, it extends its impact to metallurgy, chemical machinery, transportation, railways, and beyond.

- Power Industry

Ensures the purity of transformer oil, safeguarding transformers and ensuring continuous, trouble-free electricity distribution.

- Metallurgy and Chemical Machinery

Preserves transformer oil quality in demanding industrial environments, enhancing equipment durability and operational reliability.

- Transportation and Railways

Maintains cleanliness and integrity of transformer oil in locomotives and railway infrastructure, critical for efficient power distribution.

- Diverse Industrial Applications

Adaptable to various industries, filtering not only transformer oil but also other critical imported oils, ensuring optimal equipment performance.

Enables real-time maintenance with on-site filtration, minimizing downtime and enhancing overall maintenance efficiency.

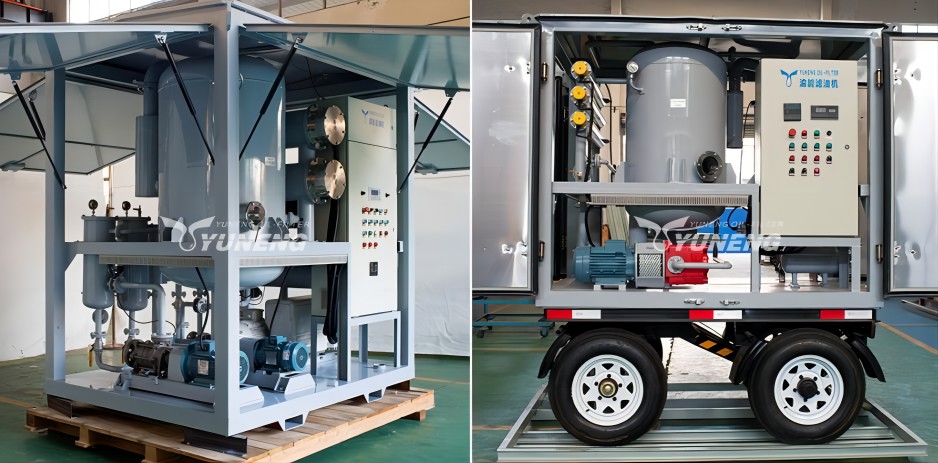

YUNENG ZJA Double Stage Transformer Oil Filtration Machine

Double-stage transformer oil filtration machines are invaluable assets for maintaining optimal transformer performance and safety. Their versatility, efficiency, and environmental benefits make them a strategic investment for any power utility or industrial facility. By understanding the Working Principles, advantages, and applications of these machines, you can make informed decisions to ensure the health and longevity of your critical electrical equipment.

YUNENG is an experienced transformer oil filtration machine manufacturer, you can contact us for inquiries. Various types of industrial transformer oil filter machines for sale can be produced.

Our advantages:

- Advanced dual-stage filtration: Combining coarse and fine filters ensures meticulous removal of both large and minute particles.

- High vacuum technology: Deeply removes moisture and dissolved gases, maximizing oil purity and insulation.

- User-friendly operation: A simple interface and automated processes make operation efficient and reliable.

- Robust construction: Durable materials and meticulous craftsmanship ensure long-lasting performance.

- Versatility: Applicable to a wide range of transformer types and oil viscosities.

If you are in any need, contact us, and our pre-sales customer service staff and after-sales customer service staff will reply to you as quickly as possible.