Applications of Vacuum Pump Systems in Transformer Maintenance

Table of Contents

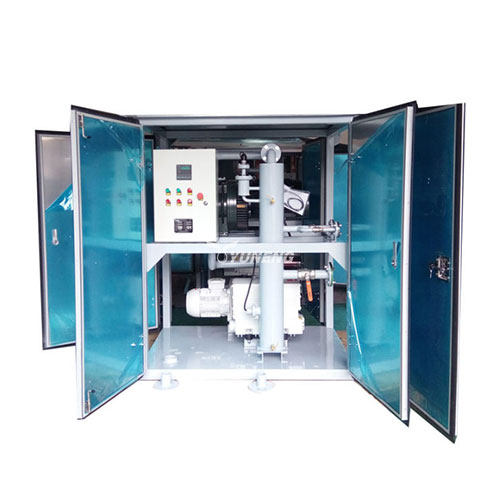

The use of vacuum pump systems stands out as a game-changer in the realm of transformer maintenance. These systems are not only pivotal in addressing common issues faced by transformers but also play a significant role in enhancing their overall performance and longevity. This article delves into the diverse ways vacuum pump systems can be utilized within the context of transformer care, focusing on three primary areas: vacuum drying, vacuum measurement techniques, and vacuum treatment for tap changers.

Comprehensive Utilization of Vacuum Pump System in Transformer Maintenance

Vacuum pumping system is an integral component in transformer maintenance, serving several critical functions to ensure the optimal performance and longevity of these devices. Three principal applications highlight the versatility and indispensability of vacuum pumping systems in transformer care:

1. Moisture Elimination and Insulation Protection

- Issue Addressed: Moisture is a pervasive enemy of transformers, undermining insulation quality, accelerating corrosion, and weakening electrical conductivity. This degradation can culminate in operational inefficiencies and potential safety hazards.

- Solution: Vacuum drying techniques involve the creation of a low-pressure environment surrounding the transformer’s core and winding. This setting accelerates the evaporation of trapped moisture, especially pertinent during the installation of new units or the refurbishment of existing ones. Effective removal of moisture enhances the dielectric strength of insulation materials, safeguarding against failures precipitated by moisture-related electrical breakdowns.

Moreover, vacuum drying is instrumental in the dehydration of insulating oil. Given that water can easily dissolve in oil, causing insulation properties to deteriorate, this process acts as a preventive measure against further damage. Vacuum drying permits the secure elimination of both free and dissolved water without harming the oil, preserving its integrity and operational efficacy.

2. Precision Measurement Post-Vacuum Extraction

- Importance of Measurement: Upon completion of vacuum drying procedures, accurate assessment of the achieved vacuum level is essential for two reasons:

- Verification of Moisture Removal: Utilizing high-precision vacuum gauges, technicians validate whether the targeted pressure reduction was accomplished, ensuring complete moisture evacuation. This validation informs decisions regarding additional drying cycles or readiness for oil refilling.

- Diagnostic Utility: Monitoring vacuum levels over time reveals potential leaks within the transformer’s casing or connections. Unanticipated increases in pressure may indicate faulty seals or joints, necessitating prompt repairs to forestall re-moisturization that could compromise earlier drying efforts.

3. Enhanced Performance of Tap Changers Through Vacuum Treatment

- Critical Functionality: Tap changers play a crucial role in voltage adjustment, adapting to fluctuating load demands and maintaining consistent power supply stability. Vacuum treatment during maintenance operations is pivotal for maintaining their operational integrity.

- Preventative Measures: Exposing tap changers to open-air conditions during service or part replacement introduces risks of contamination, including dust and moisture. Vacuum pumps establish a controlled environment, enabling meticulous cleaning and drying of inner components. This intervention not only clears away residue but also prevents the introduction of fresh contaminants during reassembly.

Additionally, vacuum treatment contributes to lowering contact resistance at switching interfaces inside tap changers. Lowered resistance improves electrical conductance, leading to a smoother transformer operation. The net result is a notable enhancement in the efficiency and dependability of voltage regulation systems.

These three facets illustrate the strategic importance of incorporating vacuum pumping system throughout various stages of transformer maintenance. By tackling moisture intrusion, verifying drying efficacy, and optimizing tap changer performance, vacuum pumping systems offer transformative solutions for sustaining transformer health and operational excellence.

Additional Applications of Vacuum Pump Systems in Transformer Care

Beyond the aforementioned uses, vacuum pumping systems find application in other important aspects of transformer maintenance:

- Oil Filtration Enhancements: Vacuum pumping can be integrated into oil regeneration processes to refine the insulating fluid. By subjecting the oil to vacuum conditions, contaminants like particulates and residual gases are removed, restoring its original purity and performance characteristics.

- Testing Seal Integrity Under Vacuum Conditions: Prior to reassembling transformers following maintenance activities, applying a vacuum helps verify the effectiveness of seals. Any breaches in sealing will manifest as pressure changes, alerting engineers to potential leakage sites requiring attention.

In short, the vacuum pumping system is the cornerstone of modern transformer maintenance methods. Their application involves multiple aspects, each of which makes a unique contribution to improving the health, efficiency, and life of transformers. From combating moisture through vacuum drying to optimizing voltage regulation through tap-changer processing, these systems have proven to be extremely valuable in protecting critical infrastructure.