Cost-Benefit Analysis in Investing in a Vacuum Oil Filter Machine for Transformer

Table of Contents

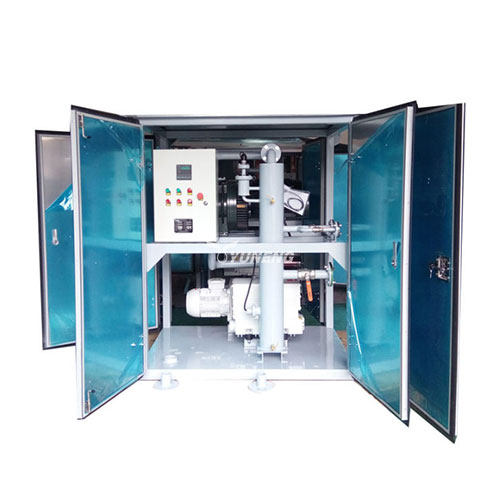

In the world of transformer maintenance, the reliability and efficiency of equipment play a pivotal role in ensuring uninterrupted power distribution. One such essential tool is a vacuum oil filter machine, designed to purify and regenerate transformer oil. When investing in such machines, a thorough cost-benefit analysis is first required to help us make the right decision.

Initial Investment Costs of Vacuum Oil Filter Machine

The upfront costs of purchasing a vacuum oil filter machine represent a significant part of the investment. These costs typically include:

- Machine Purchase Price: The cost of vacuum oil filter machines varies significantly based on factors such as capacity, automation level, and added features. Entry-level models for small-scale applications may be priced in the range of a few thousand dollars. In contrast, high-performance machines designed for industrial-scale operations can exceed $50,000.

- Installation Costs: Installing a vacuum oil filter machine may incur additional expenses, including site preparation, system integration, and hiring specialized technicians. These costs depend on the machine’s complexity and the unique requirements of the operational environment.

- Training Costs: Proper operation of a vacuum oil filter machine requires trained personnel. Employers may need to invest in training sessions to ensure that operators are well-versed in safety protocols and the efficient use of the machine.

Although the upfront investment may be significant, it serves as a foundation for long-term advantages, including lower maintenance expenses and an extended lifespan for transformers.

Operational and Maintenance Costs Costs of Vacuum Oil Filter Machine

After the initial investment, operational and maintenance costs are ongoing considerations that impact the machine’s total cost of ownership, usually including:

- Energy Consumption: The machine requires electricity to function, with energy usage varying based on its capacity and how frequently it is used. While higher-capacity machines tend to consume more power, they are often more energy-efficient for large-scale operations.

- Consumables and Spare Parts: Components such as filters and sealing materials are subject to wear and need periodic replacement. The frequency and cost of these replacements depend on the machine’s workload and design.

- Scheduled Maintenance: Routine maintenance, including cleaning, lubrication, calibration, and inspection of internal components, is crucial to prevent wear and tear. Neglecting this can lead to reduced efficiency or unexpected breakdowns.

- Repairs: As the machine operates over time, components like pumps, valves, and electrical parts may experience wear and require repair or replacement according to the usage condition.

- Labor and Training Costs: Operating and maintaining the machine efficiently requires skilled personnel. Training new staff or upgrading the skills of current employees to manage the equipment adds to the overall operational costs.

By accounting for these recurring expenses, businesses can better estimate the total cost of ownership for a vacuum oil filter machine and plan budgets accordingly. Regular maintenance ensures not only operational efficiency but also a longer machine lifespan, reducing the overall cost per use over time.

Benefits of Using Vacuum Oil Filter Machines

After understanding all the costs of investing in a vacuum oil filter, let’s take a look at the benefits that make it worth investing in:

- Prolonged Transformer Life: By effectively removing contaminants and moisture from transformer oil, a vacuum oil filter machine helps reduce wear and tear on transformer components, leading to an extended operational lifespan.

- Optimized Performance: Clean oil improves insulation and cooling efficiency, boosting the transformer’s performance and reducing energy losses.

- Reduced Risk of Transformer Failures: Regular oil filtration helps prevent degradation, which can cause transformer malfunctions or failures, thereby lowering the likelihood of costly downtime and emergency repairs.

- Environmental Benefits: These machines help regenerate and reuse transformer oil, reducing waste and supporting sustainability efforts by complying with environmental standards for oil disposal.

- Lower Operational Costs: Over time, the need for oil replacement is reduced, and transformer repairs become less frequent, resulting in significant savings on maintenance and oil costs.

These advantages make the vacuum oil filter machine a wise investment for improving transformer reliability and cutting long-term operational expenses.

Considerations Before Purchasing a Vacuum Oil Filter Machine

When looking to purchase a vacuum oil filter machine, there are a few important factors to keep in mind:

- Capacity: Make sure the machine can handle the volume of oil your transformers require. It’s crucial to choose one that can process enough oil to keep your operations running smoothly.

- Performance and Features: Check the filtration efficiency and overall performance. Look for features like automatic controls or monitoring systems, which can save time and make the machine easier to operate.

- Build Quality: Opt for a machine that’s built to last. Machines made from durable materials will need fewer repairs and replacements, saving you money in the long run.

- Energy Consumption: Consider how much energy the machine will use. An energy-efficient model can help lower operating costs over time and be more environmentally friendly.

- Maintenance and Support: Look for a machine that comes with solid after-sales support, including warranty coverage and easy access to spare parts. This ensures you can get help if anything goes wrong and minimize downtime.

- Reliable and strong ability manufacturer: Look for a reliable and strong ability manufacturer that can ensure the machine in good quality, has advanced technology, and provides fast service.

By focusing on these factors, you’ll be able to choose a vacuum oil filter machine that suits your needs and provides good value over time.

Summary

Investing in a vacuum oil filter machine is a smart decision for maintaining transformer efficiency and extending its lifespan. By considering factors such as capacity, performance, durability, energy efficiency, and after-sales support, businesses can ensure they make a well-informed purchase that will offer long-term value.

For those looking for a reliable and high-quality vacuum oil filter machine, YUNENG stands out as a trusted manufacturer. With years of experience in producing advanced filtration systems. Our products are known for high filtration capacity, energy-saving features, and excellent customer support, making them a top choice for transformer maintenance. For more information, you can visit our website: yunengoilpurifier.com