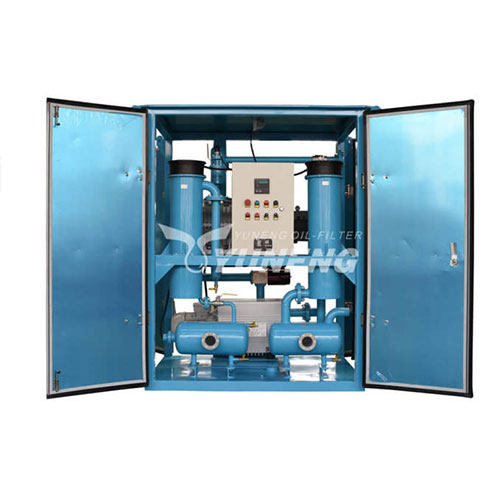

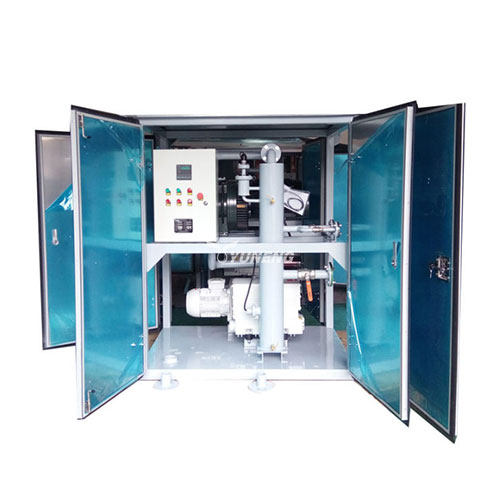

Double Stage Vacuum Pumping for Transformer

- Double-stage vacuum pumping for transformers produced by YUNENG is fast in start-up and pumping.

- Due to its speed, it is especially suitable for the vacuolization of transformers.

- Besides transformers, it can also be used for vacuumizing in various industries, including vacuum metallurgy, welding, chemistry, pharmacy, coating, and electronics.

Share to

Parameters of Double Stage Vacuum Pumping for Power Transformer

| Parameter | Unit | ZJ-70 | ZJ-150 | ZJ-300 | ZJ-600 | ZJ-1200 | |

| Power Supply | 50Hz 380V 3-Phase 4-Wire (or as requested) | ||||||

| Power Supply | KW | 4 | 6.5 | 7 | 11 | 18.5 | |

| Limit Vacuity | Pa | ≤3 | |||||

| Pumping Speed | L/S | 70 | 150 | 300 | 600 | 1200 | |

| Pumping Level | 2 | ||||||

| Connection Diameter | mm | 50 | 80 | ||||

| Size | Length | mm | 1200 | 1300 | 1400 | 1600 | 1750 |

| Width | mm | 950 | 100 | 1100 | 1200 | 1300 | |

| Height | mm | 1500 | 1600 | 1700 | 1900 | 2100 | |

| Weight | Kg | 300 | 400 | 500 | 1250 | 1560 | |

The machine size and weight will change slightly due to different configurations

What is Double Stage Vacuum Pumping for Transformer?

In most cases, a 2-stage pump will go down below 1 micron .001mm mercury vacuum. A single-stage pump is generally specified out at less than 15 microns .015mm mercury vacuum. 2 stage pumps are more expensive than a 1 stage pump because they have a high vacuum stage, what we refer to as an exhausting stage.

Advantages of Double Stage Vacuum Pumping for Power Transformer

- Double Stage Vacuum Pump System for power transformer oil filtration machine has a GIS connection.

- It features digital vacuum degree management, anti-absorption, fast start, strong vacuum pumping capacity, stable performance, and easy operation.

- There is a combination of axial fan and condenser to deal with moisture and gas from the vacuum pump and roots pump. It can prolong the time to change vacuum oil while meeting emission standards.

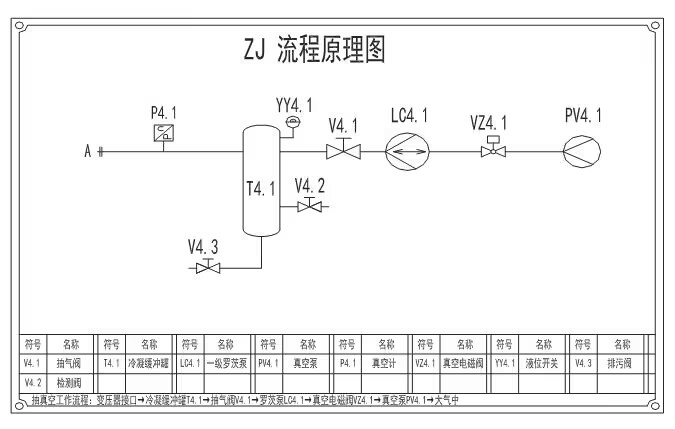

Flow Chart of Double Stage Vacuum Pumping for Power Transformer

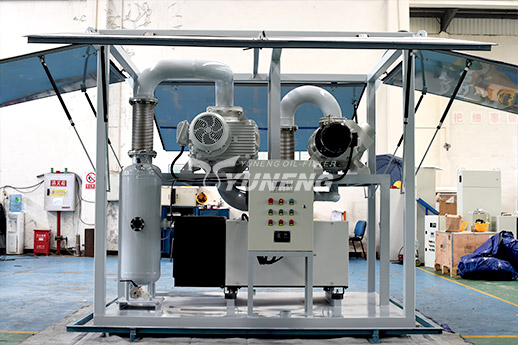

Packaging & Shipping

To be packed in iron or wooden case(s) for long-distance (ocean/air) transportation

WHY CHOOSE US

Rich Experience

Leading manufacturer in industrial oil and gas treatment with more than 25 years experiences.

Tailored Design

Specializes in making your systems suit your needs & requirements. Every system is custom engineered & custom designed.

Professional Technical Team

Professional pre-sales, in-sale and after-sales service team to meat customer’s requirement

Reliable Quality, Durable System

Top-quality components and workmanship ensure high performance