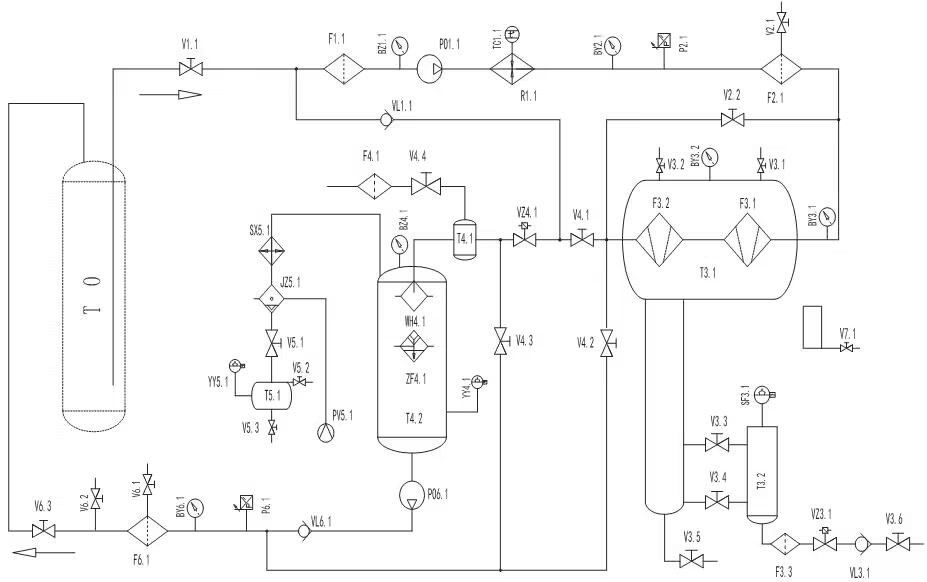

DYJC Series Turbine Oil Purifier

- The DYJC Series Turbine Oil Purifier has specific indicators like viscosity and flash point.

- It’s excellent for industrial and mining companies to clean different oil types.

- Using a two-stage or multi-stage vacuum purifier increases efficiency, reducing oil treatment time significantly.

Share to

What is Turbine Oil Purifier?

- The DYJC Series Turbine Oil Purifier is used to clean and maintain turbine systems, which can get contaminated by water and particles. This contamination can harm the turbines and lubrication systems.

- It can work with our JB regeneration system to remove sludge, and discolor oil, and reduce acidity.

- This system is widely used in various industries like metallurgy, machinery, oil, chemicals, mining, power, transportation, and manufacturing.

- It effectively cleans and rejuvenates different liquid oils like hydraulic oil, gear oil, and more. It removes moisture, gas, impurities, and light acids in the oil.

- The machine improves oil quality, restoring viscosity and performance, and ensuring the proper functioning of hydraulic, power, and lubrication systems.

YUNENG also provides lube oil purifier, hydraulic oil purifier, and other oil filters.

Features of Turbine Oil Purifier

- A wide range of vacuum dehydration.

- DCS remote control interface available.

- Special pipeline design.

DYJC Series Turbine Oil Purifier Specification

| Item | Parameter | Type Unit | DYJC-3000 | DYJC-6000 | DYJC-7800 | DYJC-9000 | DYJC-12000 | DYJC-18000 | |

| Technical Parameter | Flow Rate | L/H | 3000 | 6000 | 7800 | 9000 | 12000 | 18000 | |

| Working Vacuity | Mpa | -0.06~-0.09 | |||||||

| Working pressure | Mpa | ≤0.6 | |||||||

| Temperature Range | oC | 45-65 | |||||||

| Power Supply | 50Hz 380V 3-Phase 4-Wire | ||||||||

| Total Power | KW | 30 | 60 | 70 | 90 | 100 | 1200 | ||

| Inlet/Outlet Diameter | mm | 25/25 | 40/40 | 40/40 | 50/50 | 50/50 | 50/50 | ||

| Size | Length | mm | 2000 | 2250 | 2400 | 2600 | 2600 | 2700 | |

| Width | mm | 1550 | 1600 | 1600 | 1650 | 1700 | 1750 | ||

| Height | mm | 1600 | 1650 | 1650 | 1750 | 1800 | 1800 | ||

| Weight | Kg | 750 | 900 | 1000 | 1200 | 1500 | 1800 | ||

| Oil Treatment Index | Water Content | ppm | ≤50 | ||||||

| Kinematic Viscosity | m/s | ≤20% in comparison to the original bias value of new oil | |||||||

| Demulsibility | min | ≤15 | |||||||

| Filtering Accuracy | µm | ≤3 | |||||||

| Oil Appearance | Transparence | ||||||||

The machine size, weight will change slightly due to different configurations.

Application of DYJC Series Turbine Oil Purifier

- DYJC steam turbine oil online purifier is specially crafted for water, steam turbine, and lubricating oil units.

- Ideal for high water content oil products needing deep dehydration for better oil quality. It offers a user-friendly design, utilizing vacuum or coalescing dewatering systems separately or simultaneously.

- Suitable for treating oil products with water content below 2%, ensuring reliable operation and stable performance. It’s an ideal solution for treating oil in leaking units.

Why Do You Need to Use a Turbine Oil Purifier?

- In power plant operations, water, dust, and impurities mix with turbine oil, accelerating oxidation and forming fouling, sludge, and severe emulsification. This degrades oil performance, affecting lubrication, heat dissipation, speed regulation, and cooling. It also corrodes metal turbine parts, jeopardizing safe turbine operation.

- The turbine oil purifier ensures the safe operation of power generation systems. Primarily used in the electric power industry, it’s essential for maintaining the quality and functionality of turbine oil in power plants and stations.

What is The Function of Turbine Oil Purifier?

- Through turbine oil purification, the cleanliness of turbine oil can be ensured.

- Thoroughly solve persistent problems such as oxidation and deterioration of turbine oil

- Greatly extend the service life of turbine oil and reduce the discharge of waste oil.

- There is no need to stop the machine for an oil change, which reduces the loss of machine downtime.

What are Turbine Oils? & What Can a Turbine Oil Be Used for?

- Turbine oil is crucial for lubricating turbine generator parts, reducing friction-generated heat, and carrying away heat from high-temperature steam throughout the turbine.

- It serves as the medium for the speed control system of steam turbines and various hydraulic control valves.

If turbine oil deteriorates, it can lead to equipment damage due to poor lubrication. Additionally, it might cause rust, corrosion, blockages, and jamming in the speed control and protection devices.

What is the Reason for the Deterioration of Turbine Oil?

1. The temperature is too high

Turbine oil in operation continuously circulates in the system, and the oil temperature continues to rise. High temperature can easily lead to deterioration of oil quality.

2. Water in the turbine oil

The entry of water into the turbine oil will accelerate the aging and emulsification of the oil. And it also interacts with additives in the oil, causing it to break down and equipment to rust.

3. Impurities or dust particles enter the oil.

Due to the poor sealing of the fuel tank, air and particulate matter such as magazines and dust in it enter the turbine oil. At high temperatures, the oxidative deterioration of the oil will be accelerated.

WHY CHOOSE US

Rich Experience

Leading manufacturer in industrial oil and gas treatment with more than 25 years experiences.

Tailored Design

Specializes in making your systems suit your needs & requirements. Every system is custom engineered & custom designed.

Professional Technical Team

Professional pre-sales, in-sale and after-sales service team to meat customer’s requirement

Reliable Quality, Durable System

Top-quality components and workmanship ensure high performance