Enhancing Transformer Oil Performance Through Filtration and BVD Testing

Table of Contents

Transformers are the backbone of our electrical infrastructure, converting voltages to transport power across distances. For these transformers to work reliably, they require effective insulation, which is often provided by transformer oil. However, this oil isn’t just a passive component. Its quality, particularly its Breakdown Voltage (BDV), plays a crucial role in the safe and efficient operation of transformers. In this article, we’ll dive into the essentials of transformer oil BDV, exploring its importance, how it’s measured, the factors that affect it, ways to improve it, and where to source equipment that can help maintain it.

What is Transformer Oil Breakdown Voltage (BDV)?

The Breakdown Voltage (BDV) of transformer oil is a measure of its insulating strength. It represents the maximum voltage that the oil can withstand before it loses its insulating properties and allows current to pass through. BDV is expressed in kilovolts (kV), and higher BDV values generally indicate a cleaner and more effective insulating medium.

Transformer oil serves two main purposes: it insulates the windings and core from each other and dissipates heat generated within the transformer. For transformers to operate efficiently, the oil must retain its insulating capabilities under various stresses. A low BDV in transformer oil can increase the risk of electrical discharges, leading to transformer failure, damage, and even safety hazards.

In the power industry, BDV testing is a standard maintenance practice to ensure that transformer oil is in optimal condition. The test is quick and cost-effective, providing a direct indication of the oil’s insulation strength.

How to Measure Transformer Oil Breakdown Voltage

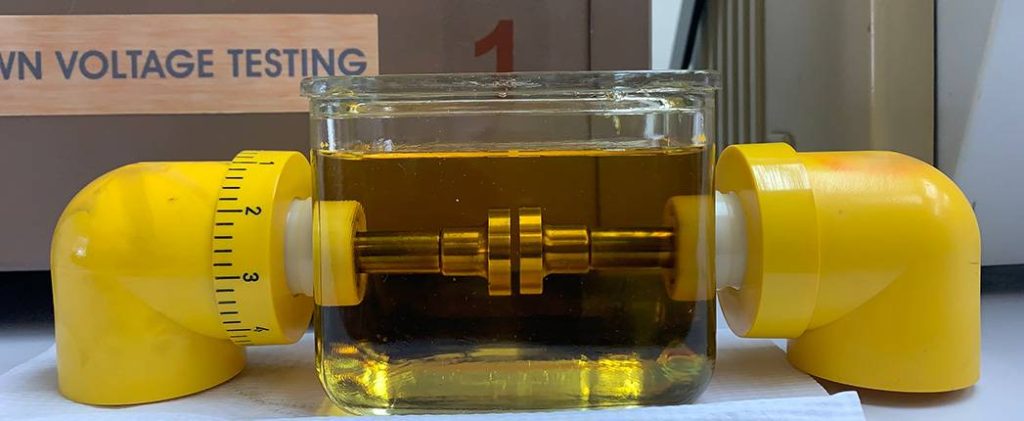

The most common way to measure the BDV of transformer oil is by using a transformer oil BDV tester. This device applies a controlled, steadily increasing voltage across two electrodes submerged in the oil sample until a breakdown occurs. The voltage at which the oil can no longer resist the electrical stress is recorded as its BDV.

Here’s a step-by-step guide on how to measure BDV using a transformer oil BDV tester:

- Preparation: Start by ensuring that the tester and the oil sample are at the correct testing temperature, typically around 20°C (68°F) to minimize the effect of temperature on the reading.

- Sample Handling: Take a representative sample of transformer oil, ensuring it’s free from contaminants. Proper sampling containers should be used to prevent moisture or particulates from entering the oil.

- Setting Up: Pour the oil into the test cup of the BDV tester, submerge the electrodes, and ensure they are at the correct spacing, as specified by testing standards (usually 2.5 mm to 4 mm apart).

- Testing: Start the BDV tester. The voltage will gradually increase across the electrodes until a breakdown occurs. The voltage at this point is recorded as the BDV.

- Repeat and Average: For accuracy, the test should be repeated at least six times, and the final BDV value is the average of these measurements.

Industry standards, such as those specified by ASTM D1816 or IEC 60156, outline specific guidelines for BDV testing procedures, including electrode configuration, oil temperature, and acceptable BDV ranges based on transformer specifications.

What Factors Affect Transformer Oil Breakdown Voltage

Several factors can impact the BDV of transformer oil, and understanding them is crucial for diagnosing issues and determining when oil treatment is necessary.

- Moisture Content: Moisture is one of the most significant threats to transformer oil BDV. Water molecules within the oil reduce its insulating strength, forming conductive paths that allow electrical discharges to occur at lower voltages. Even a small increase in moisture content can cause a substantial drop in BDV, so it’s vital to keep transformer oil as dry as possible.

- Temperature: The temperature of transformer oil affects its viscosity, dielectric properties, and the rate of chemical reactions occurring within the oil. Higher temperatures tend to increase the presence of dissolved gases and degrade the oil over time. It’s recommended to test BDV at controlled temperatures to reduce variability in results.

- Contaminants: Transformer oil can accumulate various contaminants, including particulates, metal ions, sludge, and dissolved gases. Each of these impurities can lower the oil’s dielectric strength by creating conductive paths or interfering with the oil’s insulating properties. Particulate contamination, for example, can form microscopic bridges between electrodes, reducing BDV.

How to Improve Transformer Oil Breakdown Voltage

Maintaining and improving the BDV of transformer oil is essential to extending transformer life and ensuring reliable operation. There are several effective methods for enhancing BDV:

- Transformer Oil Filtration Plant: One of the most effective methods to restore the quality of transformer oil is through oil filtration. Transformer oil filtration plants are specifically designed to remove impurities, including moisture, gases, and solid particles. These plants use a combination of filtration, heating, and vacuum treatment to purify the oil and improve its insulating properties. Regular filtration can significantly boost BDV and prolong the life of transformer oil.

- Vacuum Dehydration Machine: Moisture removal is a priority when aiming to improve BDV. Vacuum dehydration removes water by exposing the oil to a vacuum and elevated temperatures. This process converts water into vapor, which is then removed, leaving the oil dry. Dehydration is essential for improving BDV, especially in transformers exposed to humid environments.

- Degassing: Transformer oil can contain dissolved gases, which can lower BDV and affect oil stability. Degassing is a method used to remove these gases, especially those that may have formed due to transformer operation or chemical reactions within the oil. This process enhances BDV and reduces the risk of internal discharges.

- Other Conditioning Techniques: Additional methods, such as heating and magnetic separation, can also help improve BDV. Heating the oil reduces its viscosity, which facilitates the removal of water and contaminants. Magnetic separation can remove ferromagnetic particles, which can interfere with the oil’s insulating properties.

Where to Find Transformer Oil Filtration Plants

For organizations or individuals responsible for transformer maintenance, sourcing reliable filtration equipment is essential for effective BDV improvement. Transformer oil filtration plants are available from a variety of manufacturers, each offering different models and configurations based on transformer capacity, desired processing speed, and filtration technology.

When selecting a supplier, consider factors such as:

- Product Specifications: Ensure the filtration plant’s specifications match your transformer’s needs in terms of processing speed, filtration capability, and oil capacity.

- Manufacturer Reputation: Established manufacturers, such as Yuneng, have built reputations for quality and reliability. Checking customer reviews, product warranties, and after-sales support can provide insight into the manufacturer’s reliability.

- Cost and Return on Investment: While transformer oil filtration plants can be an investment, they offer significant cost savings in the long term by extending transformer life and preventing costly repairs.

Examples of leading manufacturers in the industry include Yuneng, which provides high-quality, customizable filtration plants for transformer oil maintenance. Researching and consulting with manufacturers can help you determine the most suitable solution based on your transformer’s operating environment and maintenance needs.

In Summary

Transformer oil BDV is a critical parameter that influences the overall performance and safety of transformers. Regular BDV testing, combined with methods to maintain and enhance oil quality, can significantly improve transformer reliability and longevity. By understanding what factors affect BDV, how to measure it, and how to restore it when necessary, transformer operators can prevent potential failures and ensure stable energy transmission. Consistent BDV monitoring and maintenance not only protect transformers but also play a vital role in keeping our electrical systems running smoothly and safely.