Four Features Every Great Turbine Oil Purifier Should Have

As for the turbine oil purifier, there are many types. If you choose one great turbine oil purifier, you need to know about the turbine oil purification system. Thus, this article will introduce eight features of every great turbine oil purifier.

A brief introduction to the turbine oil purification system

Turbine oil purifier applies advanced “coalescence separation” technology for dehydration, with high dehydration efficiency and a strong capacity, especially for separating a large amount of water in the oil. It has the incomparable advantages of vacuum and centrifugal methods and can break all the oil-water emulsification structures in the medium. Through the filtration of the particle filtration system, the cleanliness of the medium can be stably controlled in the state required by the system. It is to ensure the cleanliness of the oil. Besides, it not only changes the physical and chemical properties of the oil but also prolongs the service life of the oil. It has the characteristic of low operating costs, excellent system configuration, and continuous work performance. Thus, it is suitable for online operations.

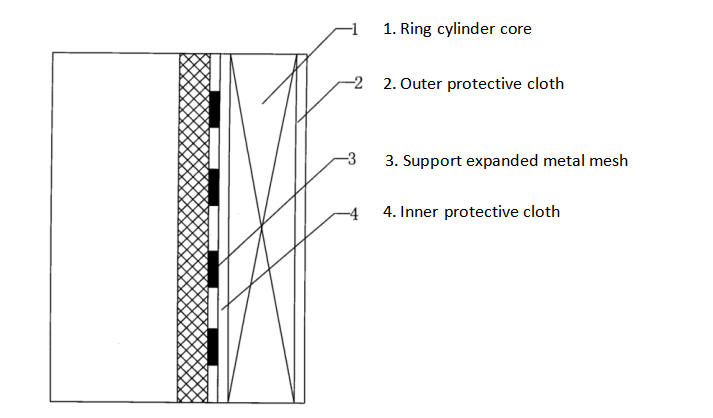

The turbine oil purifier uses high-efficiency and multi-layer filter media, the pore size is increased layer by layer. When the fluid flows through the filter medium, the little droplets pass through the filter holes and gradually converge into large droplets. These large droplets are separated from the continuous phase flow. A particular filter element made of hydrophobic, lipophilic fibers allows the natural separation of water and oil.

Four features of every great turbine oil purifier

1. Owning particle filtration system

The oil first passes through an oil suction filter with a filtration precision of 150um to protect the oil pump from being damaged by large particle pollutants. And then the oil enters the high-efficiency filter with a precision of 3um to protect the coalescence separation filter element. After the oil passes through the coalescing separator, it enters the outlet filter for processing. 1μm to 3μm filter elements can be selected as required to ensure that the cleanliness of the oil entering the user’s fuel tank reaches the design target. The fine filter element made of inert inorganic fibers with gradient pore size through the particular consolidation method and particular wrinkling method has the advantages of high precision, high dirt holding capacity, and low flow resistance. The filter element has both coarse and fine purifier functions, which avoids the cumbersome layout of the filter element.

2. Owning a coalescing system

The oil is pumped into the turbine oil purifier. Firstly, it enters the coalescing filter element. Due to the unique polar molecular structure of the coalescing filter element material, the free water and emulsified water in the oil coalesced into bigger water droplets after passing through the filter element. It sinks into the water storage tank under the action of gravity.

3. Owing separation system:

After the oil passes through the coalescing filter element, it will enter the separation filter element. Before that, the larger water droplets in the oil settled under the container, but smaller water droplets are still in the container. The reason is due to the action of gravity. Under the action of inertia, it will go up with the oil until the separation filter element. The separation filter element consists of special hydrophobic material. When the oil passes through the separation filter element, the water droplets are blocked from outside the filter element. At the same time, the oil enters the filter element and is finally discharged from the liquid port. The water droplets blocked outside the filter element gather with each other and gradually increase in size. And then settle into the water storage tank at the lower part of the container due to gravity.

4. Automatic drainage system:

The separated water is stored in the water storage tank, and the oil-water interface can be measured by the oil-water interface meter. When the height of the interface reaches the set upper limit value, the solenoid valve at the bottom of the water storage tank will be opened. Next, the accumulated water will be discharged through the water outlet. When the water level drops to the set lower limit position, the solenoid valve will close, stop the drainage, and repeat the next cycle. If the water level reaches a certain set limit below the lower limit, the system will be turned off with an alarm. The number of drainage is recorded by counter 1 and counter 2. The accumulated drainage can be calculated, according to the cumulative number of drainage and the volume of each drainage.

Recommended turbine oil purifier: JT series turbine oil purifier

If you want to find a better turbine oil purifier, here is one you can choose. It is called the DYJC series turbine oil purifier. This lubrication oil purifier owns the above four features. A turbine oil purifier is a machine for filtering light oil, turbine oil, and lubricating oil with kinematic viscosity below 46mm2/s. It has high efficiency and a good effect in filtering lubrication oil. The lubrication oil purifier applies to power plants, power stations, all industrial and mining enterprises, etc.