How Important BDV Test in Transformer?

Transformers serve as the workhorses of power transmission and distribution systems, their reliable operation underpinning the very flow of electrical energy. Ensuring their consistent performance hinges upon meticulous maintenance practices, with the Breakdown Voltage (BDV) test ranking as an indispensable tool in this endeavor. This article delves into the technical intricacies of the transformer BDV test, elucidating its significance in safeguarding transformer health and maximizing operational efficiency.

The Crucial Role of Transformers and Insulation

Within the intricate web of power systems, transformers act as lynchpins, facilitating granular adjustments in voltage levels to enable efficient transmission and distribution across diverse scales. At the heart of this crucial functionality lies the transformer oil, serving a dual role as both an insulator and a coolant. This dielectric fluid functions as a critical barrier, suppressing internal current flow and safeguarding the integrity of the intricate internal windings, thereby preventing catastrophic insulation breakdown.

Expanding upon the technical details:

- Voltage Level Adjustments: Transformers employ the principle of electromagnetic induction to either step up (increase) or step down (decrease) voltage levels based on specific needs. This ability facilitates efficient power transmission over long distances with minimal losses and enables voltage level adjustments at various distribution points for diverse applications.

- Dielectric Fluid: The transformer oil, typically a highly refined mineral oil or synthetic alternative, possesses excellent electrical insulating properties. This characteristic prevents current flow between the conductive windings within the transformer, ensuring their integrity and preventing short circuits.

- Cooling Mechanism: Additionally, the transformer oil serves as a coolant, absorbing heat generated by the transformer’s internal losses and dissipating it through external radiators or heat exchangers. This thermal management is crucial for maintaining optimal operating temperatures and preventing thermal degradation of the transformer insulation.

What is the Role of the BDV Test in Transformer Performance Analysis?

The BDV test serves as a window into the health of transformer oil, offering crucial insights into its insulating prowess. This standardized procedure measures the maximum voltage the oil can withstand before succumbing to electrical breakdown. A higher BDV value signifies robust insulating properties, while a lower value indicates potential contamination, degradation, or internal issues.

A. Demystifying Electrical Insulation

Transformer oil’s insulating efficacy hinges upon its ability to suppress current flow between conductors. The BDV test measures this resistance, expressed in kilovolts (kV). As the applied voltage gradually increases, the oil eventually reaches a critical point – the breakdown voltage. At this point, the oil’s insulating capability fails, and current abruptly conducts through it. This breakdown point reflects the oil’s dielectric strength and serves as a crucial indicator of its overall health.

B. Diagnosing Transformer Ailments

A comprehensive BDV test not only pinpoints the breakdown voltage but also acts as a diagnostic tool, shedding light on a multitude of potential transformer issues:

- Contamination: The presence of moisture, dirt, or gaseous impurities in the oil can significantly reduce its dielectric strength, leading to lower BDV values. These contaminants can originate from external sources like leaks or internal issues like overheating.

- Oil Degradation: Over time, transformer oil undergoes natural aging, leading to the formation of byproducts like sludge and oxidation products that compromise its insulating properties. Reduced BDV serves as a key indicator of such degradation, allowing for timely intervention.

- Internal Arcing: Partial discharges or arcing within the transformer can generate harmful byproducts that contaminate the oil and weaken its insulation. This can be caused by various factors like loose connections or insulation defects and is reflected in a lowered BDV.

By promptly identifying these issues through regular BDV testing, preventive maintenance measures can be implemented, mitigating the risk of catastrophic transformer failures and ensuring seamless power delivery.

C. Optimizing Performance and Ensuring Efficiency

The benefits of BDV testing extend far beyond mere diagnostics. By incorporating BDV analysis into maintenance routines, utilities can reap significant rewards:

- Optimized Maintenance Schedules: Regular BDV monitoring establishes trends in oil health, enabling maintenance to be targeted based on actual needs rather than arbitrary intervals. This data-driven approach optimizes resource allocation, minimizing unnecessary downtime and maximizing efficiency.

- Extended Transformer Lifespan: Early detection of issues through BDV testing allows for timely remedial actions, such as oil filtration or replacement. This prevents further degradation and ultimately extends the transformer’s service life, deferring costly replacements and minimizing downtime.

- Safeguarding Grid Reliability: Healthy transformers, ensured by consistent BDV monitoring, translate to a more reliable and resilient power grid. This minimizes the risk of outages and disruptions, ensuring a stable and secure supply of electricity for consumers.

What is the Transformer BDV Test Procedure?

The transformer BDV (Breakdown Voltage) test procedure is a standardized method for evaluating the dielectric strength of transformer oil, which is crucial for its insulating properties and overall health. Here’s a breakdown of the key steps:

A. Essential Equipment

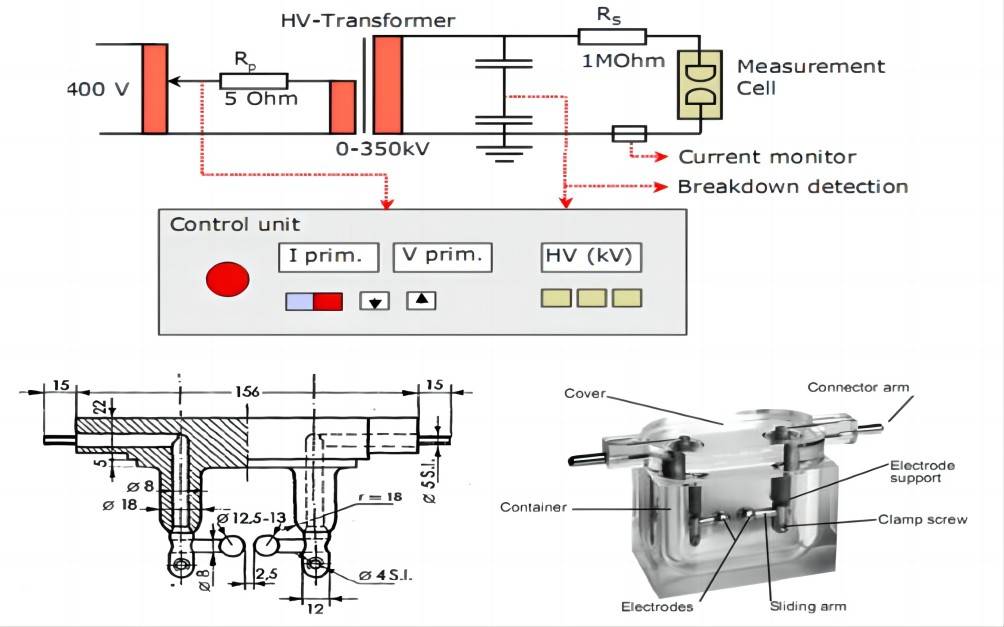

The BDV test relies on a specialized apparatus known as a transformer oil BDV tester, comprising several key components:

- High Voltage Transformer: This transformer generates a steadily increasing AC voltage applied to the oil sample via an adjustable control system. The voltage range and output stability are critical for accurate and repeatable measurements.

- Electrodes: Immersed in the oil sample, these electrodes facilitate the application of voltage and measurement of the breakdown current. The electrode material, geometry, and spacing are carefully designed to ensure a uniform electric field and minimize edge effects.

- Stirring Mechanism: This mechanism ensures uniform oil temperature throughout the sample during the test, minimizing localized heating that could influence the breakdown voltage. The stirring speed and type of mechanism are selected to avoid introducing air bubbles or excessive shear stress into the oil.

- Data Acquisition System: This system records the applied voltage, breakdown current, and breakdown time with high precision and resolution. It also tracks environmental parameters such as temperature and humidity, which can influence the test results.

B. Meticulous Preparation

The accuracy and reliability of the BDV test hinge on meticulous sample preparation:

- Oil Sampling: Representative samples are carefully extracted from designated transformer locations, following established protocols to avoid contamination and ensure the sample reflects the actual oil condition within the transformer.

- Degassing: Dissolved gases, such as air and moisture, can significantly impact the breakdown voltage. Vacuum degassing procedures meticulously remove these gases to obtain a representative sample for testing.

- Filtration: Particulate contaminants like dirt, metal particles, and fibers can distort the electric field and lead to inconsistent results. Filtration processes with appropriate pore size filters eliminate these contaminants.

- Temperature Control: The oil sample is maintained at a standardized temperature, typically 20°C, throughout the test. This ensures consistent results and avoids temperature-induced variations in the breakdown voltage.

C. Executing the Test

The BDV test follows a well-defined procedure:

- Voltage Application: The test begins with a low voltage application, typically below 1 kV. The voltage is then gradually increased at a constant rate, usually 2 kV/s, following the standardized test procedure.

- Breakdown Point Monitoring: As the voltage increases, the system closely monitors the current flowing through the oil. When the breakdown point is reached, the current abruptly increases, signifying the loss of insulating ability.

- Recording Breakdown Voltage: The voltage at which breakdown occurs is automatically recorded by the data acquisition system. Multiple tests (typically 3-5) are conducted to ensure accuracy and minimize the influence of random fluctuations.

D. Data Analysis and Interpretation

The recorded breakdown voltage is a crucial data point, but its interpretation requires expertise and consideration of various factors:

- Reference Values: Each type of transformer oil has established BDV reference values based on its specifications and intended application. These values are published in industry standards like ASTM D1816 or IEC 60156. The measured breakdown voltage is compared to these benchmarks to assess the oil’s health and identify potential issues.

- Influencing Factors: Several factors can impact the BDV value, including:

- Oil Type: Different oils have varying dielectric properties, leading to different expected BDV ranges.

- Temperature: The breakdown voltage typically decreases with increasing temperature. Temperature correction factors are applied to account for this influence.

- Testing Conditions: Factors like electrode configuration, stirring speed, and the presence of dissolved gases can slightly affect the results.

- Expert Consultation: While BDV results provide valuable insights, comprehensive diagnosis, and recommendations often necessitate consultation with qualified transformer specialists. These specialists can interpret the data within the context of the specific transformer, its operating history, and other relevant factors like transformer load and maintenance practices.

By understanding the meticulous procedures and nuanced interpretation of the BDV test, we gain a deeper appreciation of its vital role in safeguarding transformer health and ensuring reliable power delivery.

Conclusion

The transformer oil BDV tester stands as an indispensable tool for safeguarding transformer health and ensuring grid reliability. Therefore, embracing the technical intricacies of the BDV test and incorporating it into routine maintenance practices is not merely an option, but a necessity for ensuring the continued performance and longevity of these critical assets, fostering a more resilient and efficient power grid for the future.