How to Choose the Right Lubrication Oil Purifier for Your Industry?

Table of Contents

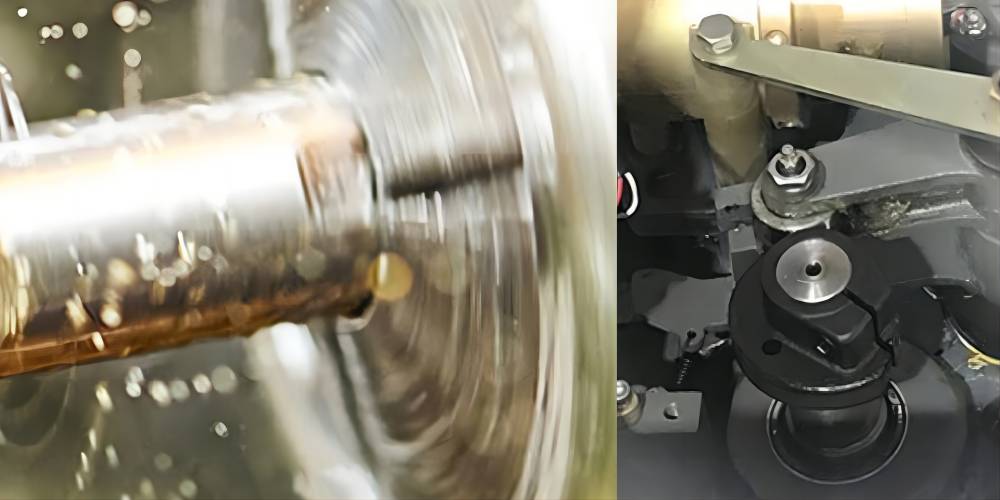

Maintaining the quality and performance of lubricants is important in any industrial setting. Lubricants play a vital role in reducing friction, preventing wear, and ensuring smooth operation of machinery. Over time, lubricants can accumulate contaminants such as dirt, water, and metal particles, which can lead to mechanical failure. Lube oil purifiers help address these issues by filtering impurities and extending the life of the oil.

Choosing the right lube oil purifier can keep machinery running efficiently and reduce downtime. This guide will walk you through the key considerations to help you choose the best option for your industry.

Role of Lubrication Oil Purifier

A lubrication oil purifier is a specialized system designed to clean and maintain the quality of lubricants in industrial machinery. Its primary role is to remove contaminants such as water, solid particles, and other impurities that can degrade the performance of the oil and lead to equipment failure. By purifying lubrication oil, the purifier extends the oil’s service life, reduces wear and tear on machinery, and enhances operational efficiency.

In industries where heavy machinery or complex systems operate under extreme conditions, such as manufacturing, power generation, marine, and transportation, oil contamination can have severe consequences. Lubrication oil purifiers play a critical role in ensuring that the oil maintains its optimal properties, ensuring the reliability and longevity of industrial equipment.

Different Types of Lube Oil Purifiers

When selecting a lubrication oil purifier, the industry in which it will be used plays a significant role in determining the most suitable type. Different industries face specific challenges related to oil contamination, and certain purifiers are better suited for particular applications. Here’s a breakdown of the common types of lubrication oil purifiers categorized by their most frequent industry uses:

Marine and Power Generation Industries

In these sectors, large-scale machinery and engines operate under intense conditions, making water and solid particle contamination prevalent issues. The following oil purifiers are often used:

1. Centrifugal Oil Purifiers

Centrifugal purifiers are widely used in marine and power generation industries due to their ability to effectively separate water, sludge, and solid particles from oil. These purifiers utilize centrifugal force to remove contaminants and are ideal for engines, turbines, and compressors where high levels of contamination occur regularly. Their robust design ensures that they can handle heavy-duty applications, making them a go-to choice in high-contamination environments.

2. Vacuum Dehydration Oil Purifiers

In power plants and marine applications, where water contamination is particularly critical, vacuum dehydration purifiers are commonly employed. These systems use vacuum technology to remove both free and dissolved water from the oil. This is especially important in protecting turbines, generators, and hydraulic systems from corrosion and oxidation, which can occur due to water presence.

Manufacturing and Heavy Machinery Industries

In manufacturing and heavy machinery, metal particles, dirt, and sludge are common contaminants that can degrade oil quality and lead to equipment failure. Purifiers suited for these environments include:

1. Magnetic Oil Purifiers

Magnetic purifiers are ideal for industries that involve metalworking, steel production, or heavy machinery operations. They use magnetic fields to capture ferrous contaminants, such as iron particles, which are commonly generated during machining or metal processing. These purifiers help maintain oil cleanliness and extend the life of both lubricants and machinery components.

2. Electrostatic Oil Purifiers

In precision manufacturing, where even microscopic contaminants can cause damage, electrostatic purifiers are often used. These purifiers apply an electrostatic charge to trap fine particles that traditional filtration systems may not capture. They are especially useful in industries that rely on high-precision equipment, such as aerospace manufacturing, where any contamination can significantly affect performance.

Oil & Gas, Mining, and Marine Sectors

Industries such as oil and gas, mining, and marine operations often face challenges related to emulsified water and other liquid contaminants in their lubricants. Purifiers designed to handle these conditions include:

1. Coalescence Oil Purifiers

Coalescence purifiers are used extensively in oil and gas refineries, mining equipment, and marine vessels to remove water and emulsified liquids from oil. These purifiers work by forcing smaller water droplets to coalesce into larger droplets, which can then be easily separated. This technology helps protect hydraulic systems, pumps, and engines from water contamination, which can lead to corrosion and breakdowns in these industries.

Hydraulic and Turbine Systems (Across Multiple Industries)

Hydraulic and turbine systems, which are found in a variety of industries from manufacturing to power generation, are particularly sensitive to water and gas contamination. oil Purifiers used in Hydraulic and Turbine Systems:

1. Vacuum Dehydration

Hydraulic and turbine systems require extremely clean oil to function properly. Water contamination, even in small amounts, can lead to system failures. Vacuum dehydration purifiers are highly effective in these settings, removing both free and dissolved water as well as gases from the oil. These purifiers ensure that hydraulic fluid and turbine oil maintain their optimal properties, reducing wear and tear on critical components.

Precision and Aerospace Manufacturing

In industries where even the slightest contamination can have significant consequences, purifiers that provide ultra-fine filtration are essential:

1. Electrostatic Oil Purifiers

Electrostatic purifiers are ideal for removing sub-micron level particles that can impact precision machinery. In aerospace manufacturing, for example, where machinery tolerances are extremely tight, the cleanliness of lubrication oil is critical. Electrostatic purifiers ensure that the oil is free from microscopic contaminants, protecting highly sensitive equipment and ensuring smooth operations.

What Need to Consider When Choosing a Lube Oil Purifier

How to select the right lubrication oil purifier depends on several key factors that vary across industries. Each sector faces unique challenges related to oil contamination, and understanding these can help guide your decision. Here are the key considerations:

- Type of Contaminants: Identify the most common contaminants in your industry. For instance, industries dealing with water contamination, such as marine or power generation, may benefit from vacuum dehydration or coalescence purifiers. In contrast, manufacturing and metalworking industries may need magnetic purifiers to remove metallic particles.

- Operating Environment: Consider the operating conditions of your machinery. Industries with extreme temperatures, pressure, or high contamination levels require robust purification systems like centrifugal purifiers to handle heavy-duty operations.

- Oil Viscosity: Different purifiers are optimized for specific oil viscosities. Ensure the system you select is compatible with the type of oil used in your equipment.

- Regulatory Compliance: In industries with strict regulations, such as oil & gas or aerospace, choosing a purifier that ensures compliance with purity standards is essential to avoid legal and operational challenges.

Summary

Selecting the right lube oil purifier helps optimize machinery performance across a variety of industries. By understanding the role and types of purifiers—whether they are used in marine, manufacturing, oil and gas, or precision systems—you can make the right choice. Consider your specific needs and operating conditions to ensure reliable, efficient machinery operation.