Key Indicators That Your Transformer Oil Needs Regeneration

Transformers are critical components in power systems, responsible for regulating voltage and ensuring stable power transmission. The core of transformer operation is transformer oil, which is both an insulator and a coolant. However, as the usage time increases, transformer oil will degrade, thereby affecting the efficiency and safety of the transformer. At this point, it is necessary to conduct regular monitoring and maintenance, including oil regeneration. Today we will talk about several key indicators of transformer oil that need to be regenerated.

Factors Cause Transformer Oil Degradation

In fact, there are several factors that can cause the degradation of transformer oil, compromising its performance.

- One of the main factors is oxidation, which occurs when the oil is exposed to oxygen for a long time. This exposure leads to the formation of acidic compounds and sludge, which then degrade the oil and reduce its effectiveness as an insulator. Thermal decomposition can also occur in the high temperature environment of operation. This process breaks down the transformer oil, producing gases and other byproducts that ultimately reduce its insulating properties and cooling efficiency.

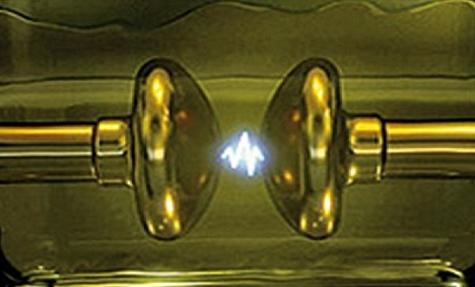

- Contaminants such as water, particulate matter, and dissolved gases can also degrade transformer oil. These contaminants often enter the oil through leaks or during maintenance activities, further diminishing its insulating strength and promoting the formation of bubbles. Electrical stress, including arcing, sparking, and corona discharges, generates by-products that contaminate the oil, reducing its dielectric strength and increasing the risk of insulation failure.

- Finally, it is the natural aging process of transformer oil. Over time, transformer oil will gradually reduce its chemical composition and physical properties. As the oil ages, its insulation and cooling capacity will gradually weaken, so regular monitoring and timely regeneration are needed to ensure the optimal performance of the transformer.

Key Indicators of Transformer Oil Degradation

Monitoring the condition of transformer oil is essential for ensuring the optimal performance and longevity of transformers. Several key indicators signal when transformer oil degradation is occurring, prompting the need for timely intervention and regeneration.

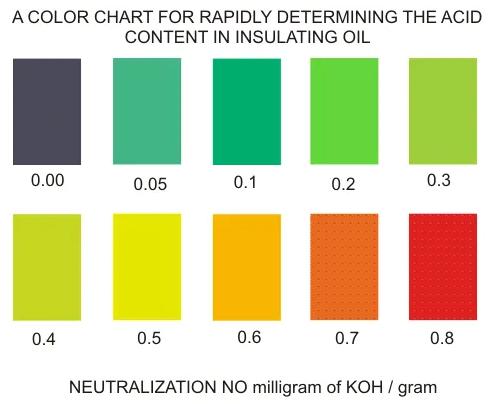

1. Acid Number

The acid number is a critical indicator of transformer oil degradation, measuring the concentration of acidic compounds within the oil. Over time, exposure to oxygen and high temperatures causes the oil to oxidize, forming acids. These acidic compounds can lead to the formation of sludge, which impairs the oil’s insulating properties and increases the risk of corrosion to the transformer’s internal components. Regular monitoring of the acid number helps in detecting early signs of oil degradation. An increase in the acid number suggests that the oil is becoming more acidic, necessitating purification or regeneration to restore its quality and prevent damage to the transformer.

2. Dielectric Breakdown Voltage

Dielectric breakdown voltage is a measure of the oil’s ability to withstand electrical stress without breaking down. Transformer oil must have high dielectric strength to effectively insulate the transformer’s windings and prevent electrical faults. Over time, contaminants such as moisture, particulate matter, and by-products of oxidation reduce the oil’s dielectric strength. A decrease in dielectric breakdown voltage indicates that the oil has a diminished capacity to insulate, increasing the risk of electrical discharges and potential transformer failures. Monitoring this parameter is crucial, as it provides direct insight into the insulating performance of the transformer oil.

3. Moisture Content

Moisture is one of the most detrimental contaminants in transformer oil. The presence of water significantly reduces the oil’s insulating properties, lowering its dielectric strength and making it more prone to electrical discharges. Moisture can enter the oil through leaks, condensation, or during maintenance activities. High moisture content can lead to the formation of bubbles when the oil is subjected to high electrical stress, further compromising its insulating abilities. Monitoring and controlling the moisture content in transformer oil is essential for maintaining its effectiveness as an insulator and ensuring the overall reliability of the transformer.

4. Dissolved Gas Analysis (DGA)

Dissolved Gas Analysis (DGA) is a diagnostic tool used to detect and measure specific gases dissolved in transformer oil. These gases are by-products of thermal and electrical faults within the transformer. Common gases detected include hydrogen, methane, ethylene, and acetylene. Elevated levels of these gases indicate potential issues such as overheating, arcing, or insulation breakdown. For instance, high hydrogen levels can signify partial discharge, while elevated ethylene and methane levels may indicate thermal decomposition of the oil. DGA provides valuable insights into the internal condition of the transformer, enabling early detection of faults and allowing for timely maintenance and oil regeneration to prevent severe damage.

Identifying and monitoring these key indicators of transformer oil degradation is crucial for maintaining the health and efficiency of transformers. Regular analysis of acid value, dielectric breakdown voltage, moisture content, and dissolved gases can detect oil degradation as early as possible and intervene in a timely manner. The use of these proactive methods can maximize the service life and reliability of transformers, reduce the risk of failure and expensive maintenance costs

Importance of Regular Oil Analysis

Regular oil analysis provides early detection of issues before they escalate. By identifying signs of degradation—such as increased acidity, moisture, and dissolved gases—timely interventions can be made to prevent major failures. This proactive approach extends transformer lifespan and ensures efficient operation by maintaining dielectric strength and cooling properties.

Financially, oil analysis leads to significant cost savings by reducing unplanned maintenance and preventing costly repairs. It enhances the reliability of the power distribution network, ensuring a stable energy supply. Additionally, it can uncover electrical or thermal faults, allowing for precise maintenance efforts.

YUNENG Transformer Oil Regeneration Machine

The YUNENG YZS series transformer oil regeneration machine provides a comprehensive solution for restoring the quality of transformer oil. This machine employs advanced technologies to remove moisture, gases, and impurities, effectively rejuvenating degraded oil. Key features of the YZS series include:

- Advanced Vacuum Filtration: Utilizes vacuum dewatering and degassing components to efficiently remove moisture and dissolved gases, improving the oil’s dielectric strength.

- High-Precision Filters: These filters capture microscopic contaminants such as sludge and oxidation byproducts, ensuring thorough purification.

- Low-Temperature Physical Adsorption: Protects the oil quality during the high-speed purification process.

- User-Friendly Design: The machine features an anti-foam structure and a two-way electronic foam monitoring system, enhancing operational efficiency and ease of use.

The YZS series is versatile and can also purify other electrical insulating oils used in cables, circuit breakers, and capacitors. By investing in the YUNENG transformer oil regeneration machine, operators can significantly reduce costs associated with oil replacement, enhance environmental sustainability by minimizing waste oil disposal, and ensure optimal performance and longevity of transformers.

For more information on the YZS series transformer oil regeneration machine, you can contact YUNNEG, and we will reply to you within 24 hours.