Lubricating Oil VS Hydraulic Oil: Key Differences to Consider

Lubricating oil and hydraulic oil are two essential fluids in industrial machinery, each serving distinct but equally crucial functions. Maintaining the quality of these oils is paramount for optimal equipment performance and longevity. Here we will explore the key disparities between lubricating oil and hydraulic oil, emphasizing the significance of oil filtration with advanced technologies like lubricating oil purifiers and hydraulic oil filtration machines.

What is Lubricating Oil?

Lubricating oil is a vital component in machinery and equipment, playing a crucial role in their smooth operation and longevity. It’s a non-compressible liquid, typically derived from petroleum or synthetic sources, designed to reduce friction and wear between moving parts.

In essence, it acts as a protective film, separating surfaces and minimizing direct contact, leading to several essential benefits:

- Reduced Friction: By creating a thin film between surfaces, oil significantly reduces friction, minimizing energy loss and heat generation. This translates to improved efficiency and fuel economy in engines and machines.

- Reduced Wear and Tear: Friction can cause significant wear and tear on moving parts, leading to premature component failure. Lubricating oil forms a barrier, protecting surfaces from direct contact and minimizing wear, extending the lifespan of equipment.

- Heat Dissipation: Friction generates heat, which can damage components and compromise performance. Oil acts as a heat transfer medium, absorbing heat and carrying it away from critical areas, preventing overheating and ensuring optimal operating temperatures.

- Corrosion Protection: Some lubricating oils contain anti-corrosion additives that help protect metal surfaces from rust and oxidation, especially in environments prone to moisture or acidic conditions.

- Sealing and Cleaning: In some applications, oil can act as a sealant, preventing leakage of fluids or contaminants, and can also help remove dirt and debris from moving parts, contributing to cleaner operation.

What is Hydraulic Oil?

Hydraulic oil is the type of liquid that creates liquid pressure energy. The main purpose of hydraulic oil is to transmit hydraulic energy. Hydraulic oil also provides lubrication between moving components. It also acts as heat transfer, sealing, lubrication, and contamination removal. It contains chemical compounds like anti-erosion additives,polyalkylene glycols, corrosion inhibitors, phthalates, adipates, oils, and butanol.

For optimal performance and lifespan, hydraulic oil must possess specific characteristics and properties:

- Viscosity: This refers to the oil’s resistance to flow. It needs to be high enough to maintain pressure but low enough to flow freely through the system, especially at startup and low temperatures.

- Incompressibility: The oil should be highly resistant to compression to ensure efficient power transmission. Even slight compression can lead to energy loss and reduced performance.

- Thermal stability: The oil should remain stable across a wide range of operating temperatures, maintaining its properties and preventing thermal breakdown.

- Anti-wear properties: The oil should contain additives that reduce wear and tear on components, extending the life of the system.

- Anti-foaming properties: Air bubbles can disrupt performance and cause cavitation (damage from collapsing bubbles). The oil should resist foaming and release any air bubbles quickly.

- Fire resistance: In some applications, fire-resistant hydraulic fluids are crucial for safety. These fluids have additives that suppress flames and reduce the risk of fire.

- Corrosion resistance: The oil should be non-corrosive to the metals used in the hydraulic system, preventing rust and damage.

Key Differences between Lubricating Oil and Hydraulic Oil

While both lubricating oil and hydraulic oil play crucial roles in machinery, they are not interchangeable. Key differences exist in their composition, properties, and intended use. Understanding these distinctions is vital for optimal performance and equipment protection.

1. Chemical Composition and Additives

- Lubricating Oil: Primarily composed of base oils (mineral or synthetic) with specific additives depending on application. Anti-wear, anti-oxidant, and anti-foam additives are common to address friction, oxidation, and foaming.

- Hydraulic Oil: Often uses similar base oils, but with different additive packages. Anti-foaming and demulsification additives are crucial for hydraulic systems prone to air bubbles and water contamination. Anti-wear and rust inhibitors are also important.

2. Viscosity Requirements

- Lubricating Oil: Viscosity varies depending on application. Engine oils are typically thicker for high-pressure environments, while gear oils may be thinner for better shifting. Viscosity index (VI) is crucial, indicating how well the oil maintains its viscosity across temperature variations.

- Hydraulic Oil: Requires low viscosity for efficient power transfer and quick response in hydraulic systems. This allows for smooth operation at a wider temperature range. High VI is essential for consistent performance across fluctuating temperatures.

3. Operating Conditions and Temperature Range

- Lubricating Oil: Typically operates in a narrower temperature range specific to the application. For example, engine oil needs to withstand high combustion temperatures, while gear oil needs to handle cold starts and high operating temperatures.

- Hydraulic Oil: Designed for wider temperature ranges to ensure consistent performance in diverse environments. They need to maintain fluidity at low temperatures while being stable at operating temperatures.

4. Compatibility with Machinery and Seals

- Lubricating Oil: Formulated to be compatible with specific machinery components and seals. Choosing the wrong oil can damage seals and lead to leaks or performance issues.

- Hydraulic Oil: Similar to lubricating oil, compatibility with seals and system materials is crucial. Some hydraulic oils may be formulated for specific types of hydraulic systems or components.

Here is a sheet summarizing the differences:

| Feature | Lubricating Oil | Hydraulic Oil |

| Chemical Composition | Base oils + specific additives (anti-wear, anti-oxidant, etc.) | Base oils + hydraulic system additives (anti-foaming, demulsifiers, rust inhibitors) |

| Viscosity | Generally higher for thicker film and wear protection | Lower for efficient power transfer and wide temperature range |

| Operating Conditions | Narrower range specific to application (engine, gearbox, etc.) | Wider range for various environments |

| Temperature Range | Specific to application (high for engines, wider for gearboxes) | Wider range for consistent performance |

| Compatibility | Specific to machinery and seals | Specific to hydraulic systems and seals |

| Primary Function | Reduce friction and wear between moving parts | Transmit power through pressure |

| Applications | Engines, gearboxes, bearings, compressors | Hydraulic systems, actuators, valves |

Oil Purifier’s Role in Solving the Filtration Problems

As lubricating oil and hydraulic oil serve distinct yet crucial roles in industrial machinery, ensuring their quality is vital to maximizing equipment performance and lifespan.

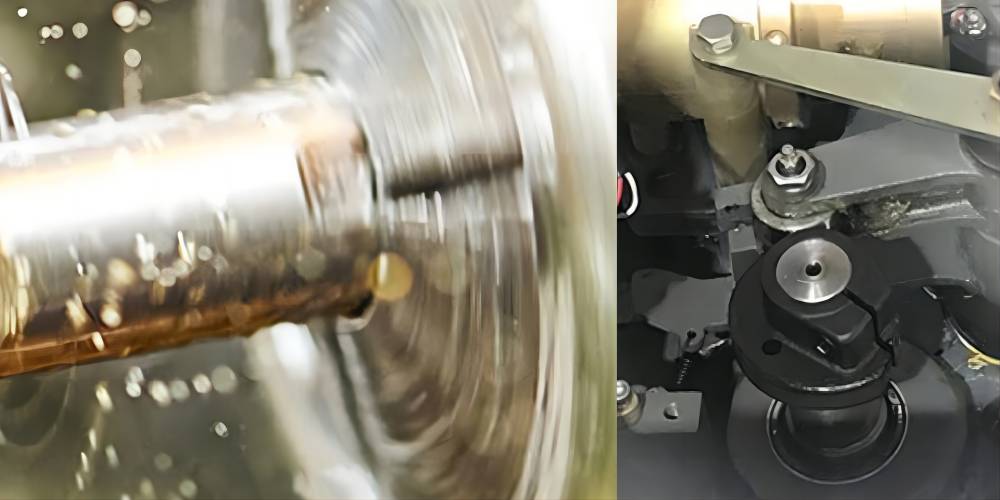

YUNENG has developed ZJC series hydraulic oil filtration machine and JT Series Lube Oil Purifier to solve the filtration problems of lubricating oil and hydraulic oil. They are specially used for the filtration and purification of hydraulic oil and lubricating oil respectively.

The ZJC series hydraulic oil filtration machine is extensively utilized across a diverse range of industries, including metallurgy, machinery, oil fields, chemicals, mining, electric power, transportation, and manufacturing. It boasts the capability to efficiently process various types of oil, including waste hydraulic oil, gear oil, turbine oil, compressor oil, and refrigeration oil. The system adopts a vacuum separation system and an impurity filtration system, which can solve the problems of water filtration, particle pollution, and emulsification in hydraulic oil.

On the other hand, The JT Series Lubrication Oil Purifier combines the functions of precision filtration and high-efficiency dehydration. It uses advanced “coalescence separation” technology for dehydration, high dehydration efficiency, and strong ability, especially for the separation of a large amount of water in lube oil.

Investing in these specialized filtration solutions is an investment in your equipment’s health and productivity. By keeping your oil clean, you minimize wear, extend equipment life, and improve operational efficiency. It’s a win-win and a healthier bottom line with less downtime and lower maintenance costs.

For product inquiries, feel free to reach out to YUNENG. As a reputable manufacturer of oil purifier equipment, we provide high-quality products at competitive prices.