SF6 Gas Recovery System and Recovered SF6 Purity Detection Methods

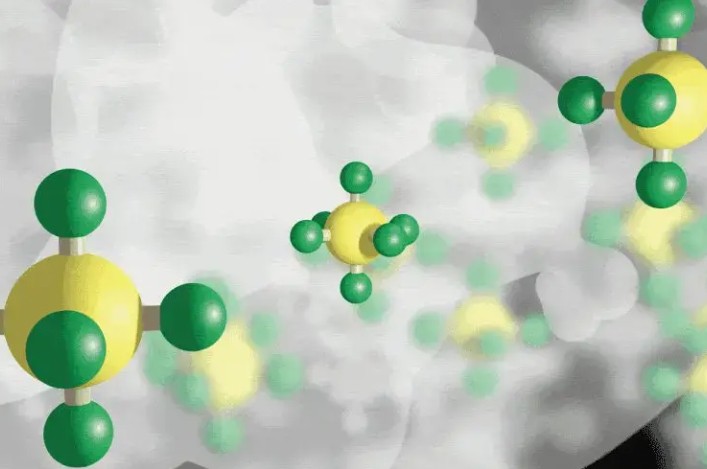

Sulfur hexafluoride (SF6) gas is a critical component in high-voltage switchgear due to its superior insulating and arc-quenching properties. However, its high global warming potential necessitates responsible management, particularly in the recovery, purification, and reuse of this potent greenhouse gas. This article delves into the key components of SF6 gas recovery units and explores the importance and various methods for detecting the purity of recovered gas.

Understanding SF6 Gas Recovery Systems

SF6 gas recovery systems are engineered to efficiently extract, purify, and store SF6 gas from electrical equipment. These systems are essential for maintaining the operational efficiency of high-voltage switchgear while adhering to environmental standards. The components of an SF6 recovery unit typically include:

- Recovery System: The recovery system is the heart of the SF6 gas recovery unit. It is responsible for extracting SF6 gas from high-voltage electrical equipment. The system utilizes compressors to create a vacuum that sucks the gas out of the equipment. This recovered gas is then routed to the subsequent stages of the recovery unit for purification and storage.

- Drying System: After the SF6 gas is recovered, it often contains moisture, which can degrade its insulating properties. The drying system removes this moisture to ensure that the gas remains effective as an insulator. This is typically achieved through the use of desiccants or other drying agents that absorb water from the gas.

- Purification System: The purification system is essential for removing impurities from the recovered SF6 gas. These impurities can include air, water vapor, and acidic gases such as SO2 and H2S. The purification process ensures that the SF6 gas is of high purity, which is critical for maintaining the performance and safety of the electrical equipment it will be reintroduced into.

- Vacuum System: Before the purified SF6 gas can be reintroduced into the electrical equipment, the equipment itself must be evacuated of any remaining gases or contaminants. The vacuum system creates a low-pressure environment inside the equipment, which is necessary for ensuring that the recharged SF6 gas does not mix with other gases and maintains its insulating properties.

- Storage System: Once the SF6 gas has been recovered, dried, and purified, it is stored in a liquid state. The storage system cools the gas to a temperature where it condenses into a liquid, which can then be safely stored in tanks. This liquid storage allows for the efficient and safe transportation of the gas until it is needed for recharging electrical equipment.

Common Methods for Testing the Purity of Recovered SF6 Gas

1. The Importance of Purity Testing in Recovered SF6 Gas

The quality of recovered SF6 gas is crucial for its safe and effective reuse in electrical equipment. Recovered SF6 gas may contain various impurities, such as air, moisture, and acidic gases like sulfur dioxide (SO2) and hydrogen sulfide (H2S). These impurities can degrade the insulating and arc-quenching properties of the gas, leading to potential equipment failure and environmental harm.

Purity testing ensures that the recovered SF6 gas meets the necessary quality standards for reuse. This testing is critical for preventing equipment damage and maintaining the performance of high-voltage switchgear. It also supports environmental sustainability by minimizing the release of potent greenhouse gases into the atmosphere.

2. Common Purity Detection Methods for Recovered SF6 Gas

1. Gas Chromatography (GC):

Gas chromatography is a high-precision technique used for separating and quantifying components in gas mixtures. In the context of SF6 gas purity testing, GC can accurately measure the levels of impurities such as air, moisture, and acidic gases. This method is particularly useful for detecting low concentrations of impurities and provides detailed information on the composition of the gas.

2. Fourier Transform Infrared Spectroscopy (FTIR):

FTIR is a rapid detection method that utilizes the infrared absorption characteristics of different gases. This technique can quickly identify major impurities in SF6 gas, making it suitable for field use. While FTIR provides a quick assessment, its precision may be lower for detecting very low concentrations of impurities compared to gas chromatography.

3. Portable Gas Analyzers:

Portable gas analyzers are comprehensive devices that combine multiple detection technologies, such as infrared spectroscopy and electrochemical sensors, to assess the quality of SF6 gas. These analyzers can simultaneously measure the purity of the gas, moisture content, and levels of acidic gases. They are particularly useful for on-site testing, offering a convenient and efficient way to evaluate the quality of recovered SF6 gas.

4. Density and Pressure Measurement:

Measuring the density and pressure of SF6 gas provides an indirect assessment of its purity. The density and pressure of the gas are influenced by its purity and temperature. This method is simple and can be used for preliminary purity assessments. However, it may not be precise enough to detect low concentrations of impurities and is often used in conjunction with other methods for a more accurate evaluation.

5. Electrochemical Sensor Method:

Electrochemical sensors are capable of detecting the decomposition products of SF6 gas, such as SO2 and H2S. This method indirectly indicates the purity and condition of the gas. While electrochemical sensors are useful for rapid on-site testing, they may require additional methods to improve detection accuracy, especially for very low concentrations of impurities.

Each recovered SF6 gas detection method has its own applicable scenarios and limitations. When selecting the most suitable detection method, factors such as the specific application environment of SF6 gas, detection accuracy requirements, and cost budget should be considered.