The Attention, Maintenance and Application of Oil Purifier

The oil purifier is a filter device. It can remove mechanical impurities, oxidation by-products, and moisture in impure oil by technical methods such as gravity, centrifuge, pressure, vacuum distillation, and mass transfer. The main usage of the oil purifier is to improve the cleanliness of mechanical and electrical oil. Thus, it can play its best performance and prolong the service life of the oil purifier.

Five attention to operating an oil purifier

1. Place the oil purifier on relatively flat ground or in the car box. You should carefully check whether the whole machine is loose, and pay special attention to the connection between the motor and the oil pump must be fastened and concentric.

2. Connect the power supply correctly. Start the oil pump and observe whether the rotation direction is correct. Otherwise, you should change the phase sequence of the power supply.

3. Connect the oil inlet and outlet pipes and tighten them. Otherwise, as the pressure increases, the oil outlet pipes will be washed out, adding unnecessary trouble.

4. After fixing the oil inlet pipe, you can start the motor button. And then the oil pump starts to work normally. The oil filtered out through the third stage is purified oil.

5. When one barrel of oil needs to be pumped out and another barrel of oil needs to be pumped, it needs to act quickly to avoid the oil pump idling for a long time. If it is too late, stop the machine and restart the machine after the oil inlet pipe is connected.

Maintenance of oil purifier

Here are five conditions to maintain the oil purifier.

1. The quality of the oil purifier determines the price of the oil purifier, so it is hoped that you must pay attention when using it. During the working process of the oil purifier, it is easy to be blocked by impurities, and the oil inflow is smaller than the oil outflow at this time.

Treatment method: remove the upper cover of the oil purifier and take out the filter screen. Clean it with the same type of clean oil, and then restore the work.

2. The noise of the oil pump increases abnormally.

Treatment method: firstly, check whether the oil pump and the connecting shaft are concentric. Secondly, whether the fastening screws are loose or fall off. The above phenomena can be ruled out after recovery.

3. Missing items are strictly prohibited, so as not to burn out the motor.

4. It is strictly forbidden to use the oil filter with the cover of the power reversing switch falling off. Otherwise, it is easy to cause electric shock accidents and cause casualties.

5. It is strictly forbidden to reverse.

Firstly, the original suction and discharge port will be reversed when reversed, which will discharge the pollutants in the original first-stage filter to the fuel tank or other refueling containers and cause pollution.

Secondly, after being turned over, the original third-stage filter element will become the first-stage filter, so the filter element will be easily blocked and cause no oil absorption.

Thirdly, the repeated reversal will also aggravate the damage of the skeleton oil seal in the oil pump, resulting in oil leakage of the oil pump.

Two applications of oil purifier

Oil purifiers have a wide range of uses and the economic value of regenerating and reusing waste oil, so let’s take a look at which industries oil purifiers are mainly used in.

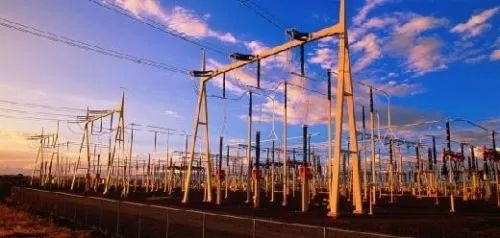

1. Power industry

The power industry has large project investment, high-profit returns, and high equipment requirements, so the power industry is a large demand for high-end oil purifier equipment. More than 70% of oil purifiers with large size, large flow, and high-end configuration are sold to the power industry. Major small and medium-sized enterprises in the field of power production are Yuneng’s important customers.

2. Chemical Industry

The petrochemical industry and its derived subsidiary industries, such as plastics, rubber, clothing, lubricants, and other industries involved in the production process of waste oil treatment and new oil quality improvement require oil purifiers. The production line in the chemical industry is generally very large in scale, so the oil consumption is also very considerable, which is an important application field of oil purifiers. The chemical industry mostly uses hydraulic oil, turbine oil, and some conventional lubricating oils. The vacuum oil purifier and lube oil purifier in YUNENG’s products can be used in this scenario.

YUNENG has been focusing on the manufacture of oil purifiers for more than 27 years, and we have rich experience in providing industrial maintenance solutions for various oil purifiers. Our goal is to help customers provide them with scientific solutions, help them reduce production costs, and improve machine service life. All types of oil filters produced by us can effectively prolong the service life of oil products, reduce equipment wear and improve production efficiency under the correct operation and use.