Troubleshooting Common Issues in Transformer Vacuum Pumping System

Table of Contents

Transformer vacuum pumping systems play an essential role in maintaining the reliability and longevity of electrical transformers, particularly those used in power transmission and distribution networks. Despite their importance, they can sometimes experience operational issues.

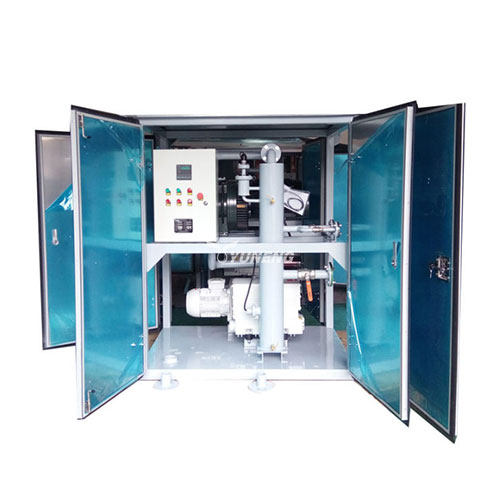

What is a Transformer Vacuum Pumping System?

A transformer vacuum pumping system is a critical tool used during the installation, maintenance, and repair of electrical transformers. Its primary function is to remove air, moisture, and gases from transformer insulation oil and internal transformer components, thereby enhancing the dielectric strength of the oil and extending the transformer’s operational lifespan. When moisture or gases are present, they can weaken the insulation, leading to increased risk of electrical faults, accelerated aging of the transformer, and reduced efficiency.

Typically, a transformer vacuum pumping system performs the following steps:

- Vacuum Creation: The system creates a vacuum inside the transformer tank, reducing the pressure so that any moisture present in the oil or insulation material evaporates.

- Degassing: Dissolved gases in the oil are extracted, which prevents issues like partial discharge and arcing within the transformer.

- Dehydration: Final removal of moisture ensures that the oil and solid insulation are as dry as possible, maximizing their insulating properties.

These systems are essential for preparing new transformers for commissioning and for revitalizing transformers during maintenance by thoroughly removing impurities that could compromise transformer performance, especially in high-voltage applications where reliability is critical.

Common Issues in Transformer Vacuum Pumping System

Transformer vacuum pumping systems are complex and can encounter several recurring issues, particularly if they aren’t well-maintained or operated correctly. Here are the five most critical issues operators often face, along with troubleshooting insights for each.

Insufficient Vacuum Pressure

When the vacuum system fails to reach its required pressure, it becomes challenging to fully remove moisture and gases from the transformer, which can affect both performance and longevity.

- Causes: Several factors can cause insufficient vacuum pressure. Common issues include worn or damaged seals, which allow air leaks into the system, blockages within the piping, or oil leakage within the vacuum pump itself. Additionally, degraded or contaminated vacuum pump oil can reduce the pump’s efficiency, and even minor air leaks in the system can significantly compromise vacuum levels.

- Troubleshooting: Begin by closely inspecting seals, gaskets, and pipe connections for signs of wear or leaks; replace any components showing damage or degradation. Next, assess the vacuum pump oil, both for adequate levels and quality—replace the oil if it appears contaminated or degraded. Any blockages in the pipeline should be cleared to ensure free flow, and routine pressure checks should be conducted to confirm the system’s integrity and identify any pressure losses early.

System Leaks and Pressure Loss

A vacuum system exhibiting leaks may struggle to maintain stable pressure levels, leading to ineffective moisture and gas removal. Operators may also notice visible oil or air leakage from various joints and seals within the system.

- Causes: Leaks often stem from worn-out or improperly installed seals, loose connections, or cracks in the pump casing and other components. Even minor leaks can drastically compromise vacuum efficiency, leading to increased operational costs and reduced transformer reliability.

- Troubleshooting: Begin by conducting a thorough visual inspection of seals, hoses, and connections to identify any signs of wear or looseness. Replace any faulty components immediately. Regularly perform vacuum pressure tests to detect leaks, using tools like ultrasonic detectors or soap solutions to pinpoint air leaks in hard-to-reach areas. Implementing routine maintenance practices, such as tightening connections and replacing aging seals, can help prevent leaks and ensure optimal performance of the vacuum system.

Vacuum Pump Failure to Start or Premature Shutdown

The vacuum pump may fail to start or may shut down unexpectedly during operation, preventing the system from achieving the necessary vacuum levels.

- Causes: This issue often stems from electrical problems, such as faulty wiring, tripped circuit breakers, or damaged motor components. Other potential causes include motor overheating, inadequate power supply, or issues with the pump’s control system. Additionally, mechanical failures, like a worn-out drive belt or obstructions in the pump, can contribute to this problem.

- Troubleshooting: Start by checking all electrical connections for damage or looseness, and reset any tripped circuit breakers or blown fuses. If the motor continues to malfunction, inspect it for internal damage or overheating. Ensure that the power supply matches the pump’s requirements. Regular maintenance, including inspecting the drive belt and keeping the pump free from debris, can help prevent these failures and ensure reliable operation.

Vacuum Pump Overheating

Overheating in vacuum pumps can manifest as unusually high temperatures during operation, potentially leading to automatic shutdowns and long-term damage to pump components.

- Causes: This issue may arise from several factors, including prolonged operation without adequate cooling, insufficient airflow due to poor ventilation, degraded or low-quality pump oil, and incorrect oil types. A blocked cooling system or malfunctioning internal components can also contribute to excessive heat buildup.

- Troubleshooting: To address overheating, ensure that the pump is situated in a well-ventilated area, free from obstructions that may impede airflow. Regularly check the oil level and quality; replace it if it appears contaminated or if it doesn’t meet the manufacturer’s specifications. Additionally, consider installing cooling systems, such as fans, to maintain optimal operating temperatures. Monitoring the pump’s temperature during operation can help identify overheating trends, allowing for proactive measures before significant damage occurs.

By understanding and resolving these issues in the transformer vacuum pump system, you can keep the transformer healthy and efficient.

Preventive Maintenance for Transformer Vacuum Pumping System

Effective preventive maintenance is crucial for ensuring the optimal performance and longevity of transformer vacuum pumping systems. Implementing a routine maintenance schedule can help mitigate potential issues and enhance system reliability. Here are key preventive measures to consider:

- Regular Oil Checks and Changes: Monitor the vacuum pump oil frequently for contamination or degradation. Regular oil changes are essential to prevent moisture and particulate build-up that can impair the pump’s efficiency. Adhere to the manufacturer’s guidelines regarding oil type and replacement intervals.

- Filter Maintenance: Replace filters regularly to ensure they effectively capture impurities and prevent them from re-entering the system. Clogged filters can reduce vacuum efficiency and increase wear on the pump, so a routine check and replacement schedule should be established.

- Seal and Hose Inspections: Conduct routine inspections of all seals, gaskets, and hoses for signs of wear, cracks, or leaks. Replace any damaged components promptly to maintain the integrity of the vacuum system. This step is critical for preventing air and moisture infiltration, which can compromise performance.

- Temperature Monitoring: Regularly check the operating temperature of the vacuum pump. Overheating can lead to severe damage, so ensure that the pump is adequately ventilated and that there are no obstructions to airflow.

By adhering to these preventive maintenance practices, operators can significantly enhance the reliability and efficiency of transformer vacuum pumping systems, reducing the likelihood of unexpected failures and costly repairs.

Where to Seek Professional Help?

Experiencing ongoing challenges with your transformer vacuum pumping system? Yuneng, a leading manufacturer of transformer vacuum pumping systems, is your trusted partner for comprehensive solutions. Our team of highly skilled engineers and technicians possesses in-depth knowledge of these systems and can provide:

- Expert Diagnosis: Accurate identification and analysis of complex system issues.

- Precision Repairs: Timely and efficient repairs using genuine OEM parts.

- Customized Maintenance Plans: Tailored maintenance programs to optimize system performance and longevity.

- 24/7 Support: Prompt response to your service needs, ensuring minimal downtime.

With Yuneng, you can rely on our decades of experience and commitment to quality to keep your transformer vacuum pumping system operating at peak efficiency.