What are the Differences Between SF6 Gas Recovery and SF6 Gas Refining?

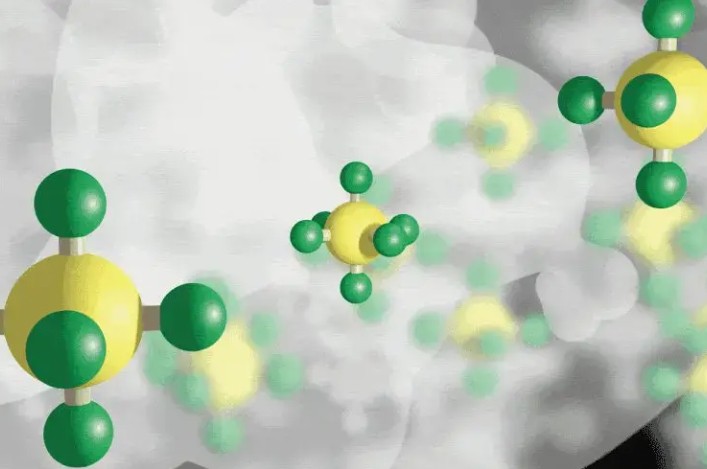

Sulfur hexafluoride, also known as SF6, is a colorless, odorless, and non-toxic gas with unique properties. It is widely used in various industries due to its excellent electrical insulation, high dielectric strength, and thermal stability. However, SF6 is also a potent greenhouse gas with a global warming potential thousands of times greater than carbon dioxide. This has raised significant concerns about its environmental impact, making responsible disposal crucial.

What is SF6 Gas Disposal

SF6 gas disposal involves various methods aimed at breaking down the molecule or capturing and purifying it for reuse. The specific method chosen depends on factors like the quantity of gas, availability of facilities, cost, and environmental considerations.

Here are some of the commonly used SF6 disposal methods:

- Plasma arc decomposition: This method involves exposing the gas to an extremely high-temperature plasma arc, which breaks down the molecules into harmless elemental components like sulfur and fluorine.

- Electron beam decomposition: This process uses electron beam bombardment to achieve similar results as plasma arc decomposition.

- Gaseous dielectric destruction: This method utilizes a corona discharge within a reactor to decompose SF6 molecules.

- Recovery and recycling: SF6 gas can be purified and reused in various applications, reducing the need for fresh production and minimizing environmental impact.

- Emission reduction technologies: Techniques like leak detection and repair programs, gas capture systems, and alternative materials can significantly reduce SF6 emissions before the need for disposal.

What is SF6 Gas Recovery and SF6 Gas Refining

SF6 Gas Recovery and Refining are crucial processes in managing a potent greenhouse gas, sulfur hexafluoride (SF6). While it offers valuable insulation and arc interruption properties in electrical equipment, its high global warming potential demands responsible handling. Let’s dive into the details.

SF6 Gas Recovery

- During the operation or maintenance of high-voltage electrical equipment, SF6 gas may need to be removed for various reasons, such as equipment servicing or repair.

- SF6 gas recovery involves the collection and purification of SF6 gas from the equipment using specialized recovery equipment. This process helps to ensure that the released gas is properly handled and does not contribute to environmental pollution.

- The recovered SF6 gas can be reused in the same equipment or, after appropriate processing, in other applications, reducing the need for new SF6 production.

SF6 Gas Refining

- SF6 gas refining is a process that purifies and enhances the quality of recovered SF6 gas.

- The refining process typically involves removing impurities and contaminants from the collected SF6 gas to meet specific quality standards and specifications.

- The purified SF6 gas can then be compressed and stored for reuse or sent for destruction if reuse is not feasible.

The importance of SF6 gas recovery and refining lies in the fact that SF6 is a potent greenhouse gas with a high global warming potential. It is essential to minimize its release into the atmosphere to mitigate environmental impact and comply with regulations aimed at reducing greenhouse gas emissions.

Key Differences between SF6 Gas Recovery and SF6 Gas Refining

Both SF6 gas recovery and refining play crucial roles in managing this potent greenhouse gas, but their approaches and outcomes differ significantly. Understanding these distinctions is key to responsible SF6 handling.

SF6 Gas Recovery

- It focuses on capturing used SF6 gas before its release into the atmosphere, often during equipment maintenance or decommissioning. Think of it as saving water from a sinking boat.

- Recovered gas is temporarily stored in specialized containers until further processing. It’s a critical first step to prevent immediate environmental harm.

- Recovery alone doesn’t guarantee reuse. The gas may be recycled or disposed of safely depending on its quality and regulations.

SF6 Gas Refining

- Takes recovered SF6 gas and purifies it to meet or exceed original specifications. Think of it as transforming the collected water into clean drinking water.

- Refining removes impurities like moisture, oil, and contaminants that compromise performance or environmental safety.

- Refined gas is ready for a second life. It can be reused in various applications, reducing the need for virgin gas production and its environmental footprint.

Here’s a table summarizing the key differences:

| Feature | SF6 Gas Recovery | SF6 Gas Refining |

| Focus | Capturing and securing used gas | Purifying recovered gas for reuse |

| Temporary or permanent? | Temporary storage for further processing | Permanent solution for gas reuse |

| Environmental impact | Prevents immediate emissions | Minimizes long-term emissions and resource consumption |

| Outcome | Gas stored for further processing | Gas ready for reuse in various applications |

Your Trusted SF6 Gas Disposal Partner: Yuneng

As a leading provider of environmental solutions, Yuneng offers comprehensive services that go beyond just disposal. We are your trusted partner for ensuring the safe and sustainable handling of your SF6 gas, minimizing its environmental impact.

Our state-of-the-art SF6 Gas Recovery Plant and SF6 Gas Refining Plant utilize advanced technologies to capture and purify SF6 gas from various sources, including electrical equipment and maintenance processes. This recovered gas can then be reused through our SF6 Gas Recycling Equipment, significantly reducing the need for virgin gas production.

By choosing Yuneng as your SF6 gas management partner, you benefit from:

- Environmentally friendly solutions: Our advanced technology minimizes the environmental impact of SF6 gas disposal.

- Reduced costs: Our SF6 gas recovery and recycling services offer cost-effective alternatives to traditional disposal methods.

- Expert support: Our team of experienced professionals provides comprehensive guidance and support throughout the entire process.

- Compliance with regulations: We ensure all services comply with the latest environmental regulations and safety standards.

Welcome to contact us for more information!