What is Double Stage Vacuum Pumping for Transformers?

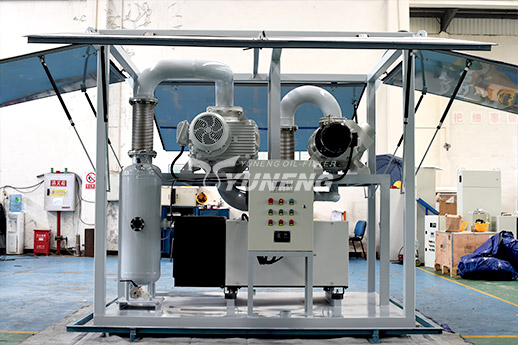

Vacuum pumping is a key link in transformer maintenance, which mainly includes two processes: vacuum pumping and oil filling. As a highly efficient vacuum equipment, the double-stage vacuum pump plays an important role in the transformer vacuum pumping and oil filling process. This equipment is usually used in many industries including power companies and substations, especially in large substations above 110KV for on-site transformer maintenance and deep treatment of new oil and imported oil.

What is Double Stage Vacuum Pumping?

Double-stage vacuum pumping is a critical process in transformer manufacturing, designed to eliminate moisture, air, and other contaminants from the transformer’s oil-filled cavity. This ensures optimal performance, minimizes the risk of electrical breakdowns, and prolongs the transformer’s lifespan.

The first stage of the process involves a roughing pump, which creates a low-pressure environment by removing a significant portion of the gases and vapors present within the transformer. This initial step sets the stage for the second stage, which utilizes a high-vacuum pump to achieve an extremely low pressure. The high-vacuum pump is capable of removing the remaining impurities, including those that are more difficult to extract due to their molecular weight or chemical properties.

The combination of these two stages is beneficial for achieving the desired level of vacuum within the transformer. Additionally, a well-evacuated transformer helps to improve its thermal performance and reduce energy losses.

Double Stage Vacuum Pump in Transformer Vacuuming and Oil Filling Process

The application principle of the two-stage vacuum pump in the transformer vacuuming and oil filling process involves the comprehensive application of vacuum technology and filtration technology. Next, we will discuss the specific principles and technical details of this process in detail.

Application Principle in Transformer Vacuuming

During the vacuuming process of the transformer, the main purpose is to remove air and other gases inside the transformer. This is a necessary step because the air contains oxygen and moisture, which may cause oxidative corrosion of the metal components inside the transformer. At the same time, the presence of air may also reduce the insulating performance of the insulating oil. Therefore, by vacuuming, the oxygen concentration and humidity inside the transformer can be significantly reduced, thereby reducing the risk of oxidative corrosion and insulation performance degradation.

The two-stage vacuum pump plays a central role in the vacuuming process. It uses a two-stage air extraction system to gradually reduce the air pressure inside the transformer.

- In the first stage, the vacuum pump first removes most of the air and other gases. This process reduces the air pressure inside the transformer to a lower level.

- Then, the second-stage vacuum pump works further to further remove the remaining small amount of gas through more precise pumping, so that a higher degree of vacuum can be achieved inside the transformer.

This two-stage pumping method not only improves the efficiency of vacuuming but also achieves a deeper vacuum effect, ensuring that there is almost no gas or moisture inside the transformer, thus laying the foundation for the subsequent oil filling step.

Application Principle in Transformer Oil Filling

After the transformer is evacuated, the oil filling process is carried out immediately. The purpose of oil filling is to inject insulating oil into the transformer. This oil is not only used to fill all the spaces inside the transformer to prevent air from entering again, but also to form a good insulation layer inside the transformer.

- During the oil filling process, the two-stage vacuum pump continues to play an important role. It can not only maintain the vacuum state inside the transformer to prevent air from re-entering the transformer but also fill the oil while evacuating the vacuum.

- This synchronous operation greatly improves work efficiency, because the vacuum state inside the transformer helps the insulating oil to penetrate into all internal gaps and structures faster and more evenly, ensuring that the insulating oil can fully cover all parts inside the transformer.

- In addition, oil filling under a vacuum can also prevent trace air or bubbles remaining in the insulating oil from affecting the insulation effect, thereby further improving the insulation performance and reliability of the transformer.

In general, the two processes of vacuuming and oil filling are inseparable, which together ensure the efficient operation and long life of the transformer. The two-stage vacuum pump provides key technical support for these two processes through its excellent vacuuming and vacuum maintenance capabilities, ensuring that the transformer is always in the best condition during production and maintenance.

How Can You Benefit From Double Stage Vacuum Pumping?

The use of double-stage vacuum pumping offers several key benefits to transformer manufacturers and maintenance professionals:

- Enhanced Reliability: By removing moisture and gases, double-stage vacuum pumping improves the dielectric strength of the insulation system, reducing the likelihood of electrical breakdowns.

- Extended Lifespan: Proper vacuuming and oil-filling procedures extend the operational lifespan of transformers, minimizing the need for frequent maintenance and replacements.

- Improved Efficiency: Transformers that undergo thorough vacuuming and oil-filling processes operate more efficiently, translating into lower energy losses and reduced operational costs over time.

- Compliance and Safety: Meeting stringent industry standards for transformer manufacturing and maintenance ensures compliance with safety regulations and enhances overall operational safety.

In summary, during the transformer vacuuming and oil filling process, the two-stage vacuum pump achieves efficient and safe treatment of transformer oil through its unique two-stage vacuum system and multi-stage filtration technology, combined with automatic control and safety protection functions. These technical features not only improve work efficiency but also ensure the operation quality and safety of the transformer.

With the continuous advancement of technology, the application of two-stage vacuum pumps in these fields will be more extensive and mature in the future.

If you are interested in other information about double stage vacuum pumping for transformers, or anything about transformer oil purify, YUNENG’ s service team will be happy to answer your questions.