Why do You Need to Measure the Breakdown Voltage of Transformer Oil?

Breakdown voltage refers to the voltage at which the dielectric breaks down. The dielectric will lose its dielectric properties and become a conductor under the action of a sufficiently strong electric field, which is called dielectric breakdown. The voltage corresponding to this time is the breakdown voltage.

The Difference Between Breakdown Voltage and Rated Voltage

The breakdown voltage is the limit voltage of the capacitor, beyond this voltage, the dielectric in the capacitor will be broken down. The rated voltage refers to the voltage that the capacitor can withstand during long-term operation, and the rated voltage is lower than the breakdown voltage. Capacitors not only work properly at rated voltage, but capacitors can also work safely at no higher than the breakdown voltage.

What are the Main Factors Affecting the Breakdown Voltage of Transformer Oil?

If impurities, gas, and water are dissolved in the transformer oil, they have little effect on the withstand voltage. If they are in a floating state, the breakdown voltage will drop significantly.

1. Moisture in the Transformer

The smaller the water content in the transformer oil, the higher the power frequency breakdown voltage. The magnitude of the breakdown voltage depends not only on the water content but also on the state of the water in the oil. In general, emulsified water has a greater impact on breakdown voltage than dissolved water.

Reducing the water content of the oil has a positive effect on slowing down the aging of the oil and improving the operational safety of the transformer. In order to reduce the water content of the oil, the oil can be treated by vacuum heating. The oil temperature is heated to 60~70°C, and a high vacuum is drawn to reduce the water content in the oil.

2. Impurities in Transformer Oil

The breakdown field strength of pure oil is very high, and when there are impurities and moisture in the oil, the breakdown voltage of the oil drops significantly. The more uniform the electric field, the greater the influence of impurities on the breakdown voltage and the greater the dispersion of the breakdown voltage. In a non-uniform electric field, impurities have little effect on the breakdown voltage.

The influence of suspended particles in oil on its dielectric strength under the action of power frequency voltage is also related to the number, size, and nature of the particles.

3. Gas Content of Oil

Gas content is one of the main control indicators of transformer oil, and gas content directly affects the insulation performance of ultra-high voltage transformers.

If the transformer oil contains air bubbles, the breakdown voltage will drop significantly. Because of the presence of air bubbles in the oil, the air bubbles can dissociate at lower voltages. Under the action of electric field force, it is easy to conduct electricity between electrodes, which will reduce the breakdown voltage of oil.

4. The Uniformity of the Electric Field

The more uniform the electric field, the higher the breakdown voltage of the transformer oil. Therefore, the power frequency breakdown voltage of the transformer oil can be increased by improving the uniformity of the electric field.

5. Oil Flow Rate

When the transformer oil flows, it will rub against the insulating material to generate static electricity. The higher the flow rate, the higher the voltage. The phenomenon that the oil flows in the transformer and generates electricity is called oil flow electrification. The electrification of the oil flow can distort the electric field of the transformer. The live voltage of the oil flow is superimposed with the test voltage. When the superimposed electric field strength exceeds the partial discharge field strength or breakdown field strength of the insulating material, the safe operation of the transformer will be endangered.

6. Temperature

For oils that are free of impurities and dry without moisture, the temperature has little effect on the breakdown voltage. However, when the temperature rises to a certain temperature, the oil molecules are ionized due to cracking, and as the temperature increases, the viscosity of the oil decreases significantly, and the electrons and ions generated by the ionization run faster due to the reduced resistance, resulting in The oil is broken down, and the breakdown voltage drops significantly.

If the oil contains impurities and water, when the temperature is low, the water in the oil is mostly suspended, and the breakdown voltage value is small. As the temperature increases, the milky water gradually becomes dissolved water and the breakdown voltage of the oil increases. But if the temperature rises to a certain level, the water in the oil evaporates and bubbles are formed in the oil. The viscosity of the oil decreases, causing moisture, impurities, and air bubbles to form conductive “bridges” in the oil, and the breakdown voltage of the oil will drop again.

Transformer oil, as a very important indicator in transformer oil, should be detected and controlled.

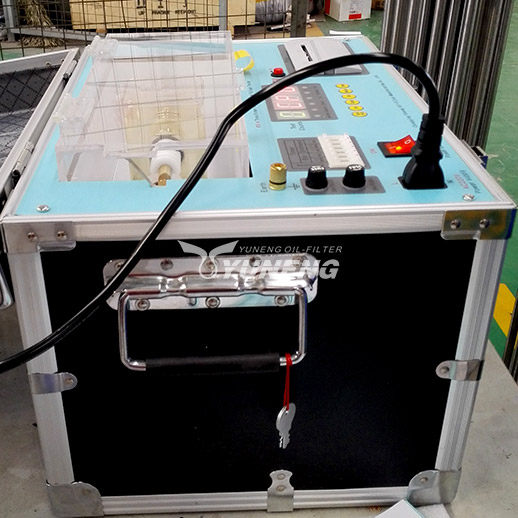

YUNENG Transformer Oil Testing Machine for BDV

YUNENG BDV transformer oil testing machine is mainly used to test the dielectric strength of various insulating oils. According to the requirements of the IEC165 dielectric strength test method of insulating oil and the feedback design of the user, through proper programming, it has functions such as automatic voltage boosting, voltage reduction, and stirring. After the breakdown of the oil medium, the high-voltage disconnection will act within 10 seconds, so that the control system part is automatically isolated, effectively ensuring the safety of personnel and equipment.

YUNENG BDV transformer oil testing machine is easy to operate, small in size, light in weight, very convenient for open-air operation, strong in anti-interference ability, and high in test accuracy. The tester is controlled by an industrial single-chip microcomputer, and special testing and anti-interference technology are applied, which greatly improves the performance of the machine.

YUNENG is a manufacturer specializing in the development and manufacture of various oil filtration machines, oil purification machines, and related peripheral products. Professional R&D and customer service teams are always at your service.