Why Transformer Manufacturers Choose Dry Air Generators for Moisture Control?

Table of Contents

Humidity control is a critical factor in transformer manufacturing. Transformers play a key role in electrical systems. However, the presence of moisture can severely affect the performance and life of the transformer. This is where dry air generators become indispensable. They are widely chosen by transformer manufacturers as an effective humidity management solution. But what exactly makes them such a popular choice?

Do You Know the Impact of Moisture on Transformers?

Moisture poses a serious risk to the operation and lifespan of transformers. Exposed to challenging environmental conditions, transformers can accumulate water through various means, such as condensation, leaks, or high external humidity. The presence of moisture can lead to several critical issues:

- Corrosion of Metal Parts: Water can lead to rust and corrosion in metal components, which may result in mechanical failures and short circuits.

- Insulation Degradation: Transformers depend on insulating materials to prevent electrical faults. Moisture weakens these materials, like paper and oil, reducing their effectiveness and increasing the likelihood of breakdowns and failures.

- Shortened Service Life: The combined effects of insulation breakdown and corrosion can significantly reduce the transformer’s lifespan, leading to costly repairs or replacements.

- Decreased Efficiency: Moisture raises dielectric losses within the transformer, causing more energy to dissipate as heat. This results in lower efficiency and can gradually damage the equipment.

These challenges underscore the critical need for moisture control in transformers to ensure their reliable, efficient, and long-term operation.

How Dry Air Generators Work for Transformer?

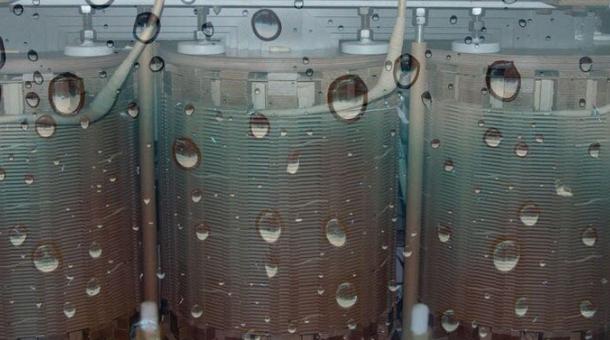

Dry air generators are essential tools used to maintain moisture-free environments inside transformers. They operate by providing a continuous flow of dry, dehumidified air into the transformer, ensuring that moisture does not compromise its components. Here’s how they work:

- Moisture Removal: Dry air generators employ advanced technologies to remove moisture, such as desiccant systems or refrigeration methods. Desiccant-based systems use materials like silica gel or molecular sieves to actively absorb moisture from the air. In refrigeration-based systems, the air is cooled to condense and eliminate water vapor. Both approaches ensure that the air entering the transformer remains free of humidity.

- Continuous Airflow: Once moisture is removed, the generator pumps dry air into the transformer at a controlled rate. This flow of dry air helps maintain a positive pressure within the transformer, preventing moisture-laden external air from entering.

- Pressure and Humidity Control: Dry air generators come with built-in sensors that continuously monitor humidity and pressure inside the transformer. If the humidity exceeds safe levels, the generator automatically adjusts its airflow to maintain a dry and stable environment.

By maintaining a steady supply of dry air, these generators protect the transformer from moisture-related issues like insulation degradation, corrosion, and reduced operational efficiency. This controlled environment helps to prolong the transformer’s lifespan and ensure reliable performance.

Benefits of Using Dry Air Generators for Transformer Manufacturers

For transformer manufacturers, using dry air generators offers a range of practical benefits that improve both the manufacturing process and the longevity of the transformers themselves.

- Longer Transformer Lifespan: Keeping moisture out of transformers helps protect the insulation and internal components, reducing the risk of degradation. This leads to a longer operating life, minimizing the need for early replacements and maximizing the return on investment.

- Better Efficiency: By ensuring that moisture does not interfere with the transformer’s operation, dry air generators help maintain its efficiency. This means the transformer operates at peak performance, reducing energy loss and the risk of overheating.

- Enhanced Reliability in Harsh Environments: Transformers are frequently placed in settings with varying temperatures and high humidity. Dry air generators help maintain optimal performance, regardless of external conditions, minimizing the risk of malfunctions.

- Lower Maintenance Costs: Regular maintenance and unexpected repairs can be costly. By controlling the moisture levels inside transformers, dry air generators reduce the chances of corrosion or electrical faults, cutting down on maintenance needs and avoiding expensive repairs.

- Boosted Safety: Moisture within a transformer can trigger serious electrical faults or mechanical problems. By keeping the internal environment dry, dry air generators help eliminate safety risks, ensuring smooth operation without endangering workers or equipment.

In summary, dry air generators provide crucial moisture control that results in reliable, efficient, and safe transformer operation. These benefits collectively contribute to reduced downtime, extended transformer life, and lower overall maintenance costs for manufacturers.

Selection Criteria for Dry Air Generators

Choosing the right dry air generator for transformer applications requires careful consideration of various factors. Key selection criteria include:

| Criterion | Description |

| Airflow Capacity | The generator must provide sufficient airflow to maintain proper pressure and moisture removal within the transformer. Ensure the system matches the required volume based on transformer size. |

| Moisture Removal Efficiency | Look for a high-efficiency system that effectively removes moisture from the air, whether using desiccants or refrigeration technologies. The goal is to consistently provide dry air with low humidity levels. |

| Reliability and Durability | Select a dry air generator built to endure continuous operation without frequent breakdowns. High-quality systems ensure dependable performance over the long term. |

| Monitoring and Control Features | Opt for models with real-time monitoring capabilities, such as humidity sensors, pressure gauges, and alerts to ensure the air quality remains at optimal levels. |

| Energy Efficiency | Choose energy-efficient models that minimize power consumption while maintaining performance. This will help reduce operational costs and increase the sustainability of the system. |

| Size and Compatibility | Ensure the generator is compatible with the specific transformer design and size. It should be appropriately sized to fit into the operational space and align with transformer requirements. |

This format allows for a quick and clear understanding of each key factor to consider when selecting a dry air generator for transformer moisture control.

Need to Invest in High Quality Dry Air Generators?

Investing in a high-quality dry air generator is important to protect your transformer and ensure consistent performance. YUNENG is a trusted manufacturer that provides advanced dry air generators that effectively remove moisture and prevent damage to transformer insulation and components. Our products are designed to operate reliably and continuously, even in challenging environments. With a focus on durability and efficiency, our dry air generators can provide long-term cost savings and enhanced transformer protection, making them an ideal choice for manufacturers who value quality and performance.

If you are interested in dry air generators, please feel free to contact us.