ZJC Series Hydraulic Oil Filtration Machine

- The ZJC series hydraulic oil filtration machine finds wide application across diverse industries including metallurgy, machinery, oil fields, chemicals, mining, electric power, transportation, and manufacturing.

- Efficiently handles various oil types such as waste hydraulic oil, gear oil, turbine oil, diesel engine oil, compressor oil, and refrigeration oil.

- Capable of swiftly dehydrating water and eliminating gas and mechanical impurities from the oil.

- Removes light acid and hydrocarbons through flashing, ultimately improving oil quality and restoring the performance of hydraulic and lube oils.

Share to

Definition of Hydraulic Oil Filtration Machine

- The ZJC series hydraulic oil purifier is meant for purifying different industrial waste oils with a viscosity below 320 mm2/s. These oils include turbine, mechanical, hydraulic, compressor, and refrigeration oils that have been contaminated by water infiltration.

- It handles emulsification and mechanical particles encountered during processing, transportation, and usage, making it an excellent choice for plant maintenance, ensuring energy efficiency and cost savings.

- YUNENG, as a manufacturer of hydraulic oil filtration machines, boasts a professional team including 14 R&D engineers, 9 after-sales service engineers, and skilled maintenance and troubleshooting engineers available for international installation and debugging.

- Additionally, YUNENG provides not only hydraulic oil purifiers but also turbine oil purifiers, lube oil purification machines, and other oil filters.

Features of Hydraulic Oil Filtration Machine

- Suitable for voltage grade ≤320 mm2/s industrial oil.

- Compact in structure, and simple in operation.

- Convenient in maintenance, low cost.

How Does Hydraulic Oil Filtration Machine Work?

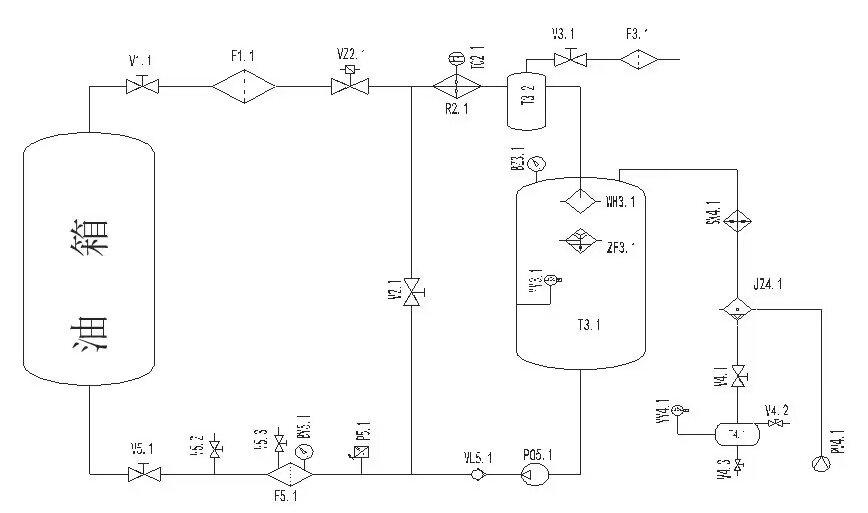

- In the ZJC series hydraulic oil purifier, the oil to be filtered moves into an electric heater due to external atmospheric pressure and the oil filter’s suction vacuum from the vacuum pump. After heating, it passes through a strong magnetic filter, removing metal particles and large impurities.

- Also, the oil carrying tiny impurities undergoes further filtration through second and third-stage filters. This process separates impurity-laden oil and directs it to a three-dimensional vacuum flash tower. Through a spray device, the oil is dispersed as a mist.

- Inside the three-dimensional flashing pall ring, a very thin oil film forms and moves downward, creating a substantial aeration area and time for aeration. This process ensures complete demulsification, dehydration, and degassing.

- The resulting gas mix, containing vaporized water and light hydrocarbons, enters a water gas separation device, a strong air condensation system, and a vacuum buffer chamber. This rapidly cools and condenses the vapor and hydrocarbons, turning them into water.

- The condensed water exits through a drain. The non-condensable gas is removed via a vacuum pump. The oil, now free from moisture, gas, and mechanical impurities, is pumped through a precision filter, effectively removing particulate impurities and providing clean, purified oil, completing the entire purification process.

Hydraulic Oil Filtration Machine Specification

| Item | Parameter | Type Unit | ZJC1.8KY | ZJC3KY | ZJC6KY | ZJC9KY | ZJC12KY | |

| Technical parameter | Flow rate | L/Min | 30 | 50 | 100 | 150 | 200 | |

| Working Vacuity | Mpa | -0.07~-0.09 | ||||||

| Working pressure | Mpa | ≤0.5 | ||||||

| Temperature Range | ℃ | 40-60 | ||||||

| Power Supply | 50Hz 380V 3-Phase 4-Wire | |||||||

| Total Power | KW | 13.5 | 33 | 65 | 97 | 127 | ||

| Inlet/Outlet Diameter | mm | 25/25 | 32/32 | 40/40 | 50/50 | 65/65 | ||

| Size | Length | mm | 130 | 155 | 190 | 180 | 185 | |

| Width | mm | 95 | 170 | 180 | 10 | 220 | ||

| Height | mm | 140 | 170 | 180 | 210 | 220 | ||

| Weight | Kg | 330 | 560 | 950 | 1300 | 1700 | ||

| Oil treatment index | Water Content | ppm | ≤50 | |||||

| Filtration accuracy | µm | 3 | ||||||

| Impurities | None ( Visual appearance) | |||||||

The machine size, weight will change slightly due to different configurations.

Why Do We Need a Hydraulic Oil Filtration Machine?

- In the process of using construction machinery and equipment, hydraulic systems are generally used to control and manage the equipment, so the quality of hydraulic oil is very important.

- Under normal circumstances, the hydraulic system should be subjected to a load test before the process of equipment control, which will contaminate the hydraulic oil in the hydraulic system during use.

- If the hydraulic oil is polluted during use, it will adversely affect the normal operation of the entire construction machinery and equipment.

- In order to solve the pollution problem of hydraulic oil, we can use hydraulic oil filtration machines to filter and purify hydraulic oil.

Sources of Hydraulic Oil Contamination

There are many reasons for oil pollution during the operation of the hydraulic system of construction machinery and equipment. It can be mainly divided into three aspects:

1. Internal generation

- During the operation of mechanical equipment, the hydraulic system generates heat due to the influence of pressure, which greatly increases the temperature in the hydraulic system.

- Hydraulic fluids oxidize when heated, producing organic substances that corrode the metal components of machinery.

- In the process of long-term oxidation and wear, the performance of construction machinery and equipment will be greatly reduced.

2. System Residues

- Hydraulic oil has good water absorption in the process of practical application.

- If the hydraulic system is in normal operation, the moisture in the air enters the hydraulic system, and after the construction machinery and equipment stop working, the temperature in the hydraulic system will drop, which will lead to the fusion of water molecules and hydraulic oil. This will have a certain impact on the quality of the hydraulic oil.

3. The outside world enters

- During the processing and assembly of construction machinery components, it is also easy to mix some external impurities into the hydraulic system, which reduces the performance of hydraulic oil in all aspects.

WHY CHOOSE US

Rich Experience

Leading manufacturer in industrial oil and gas treatment with more than 25 years experiences.

Tailored Design

Specializes in making your systems suit your needs & requirements. Every system is custom engineered & custom designed.

Professional Technical Team

Professional pre-sales, in-sale and after-sales service team to meat customer’s requirement

Reliable Quality, Durable System

Top-quality components and workmanship ensure high performance